PCB Walk-through 4: Constraints

This walk-through demonstrates how to set up differential pairs and constraints using OrCAD PCB Designer Professional. After you complete this topic, you will be able to:

- Set up a differential pair

- Specify electrical, physical and differential pair rules with Constraint Sets

To follow along, continue working with the design completed in PCB Walkthrough 3 or open the provided board file in the folder directory, PCB Walkthrough 4_Constraints.

Open in New Window

Open in New Window

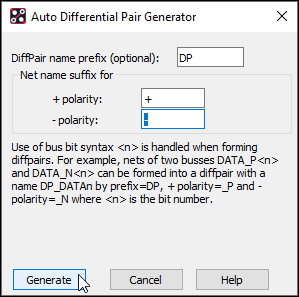

Note: If you did not define your differential pairs at the schematic level, use the following steps for definition in the PCB:

- Select Setup > Add Differential Pairs from the menu.

- Select Auto Generate.

- Assign DP_ for the name.

- Set the + polarity to +.

- Set the – polarity to –.

- Click Generate.

- Click OK to close the window.

This has generated the differential pair.

- In the Design Workflow, select Constraints > Modes.

Note: In the Modes window, select which constraints will be checked by setting the constraints “On” or “Off”. Electrical constraints are available in OrCAD PCB Designer Professional.

- Close the Mode window.

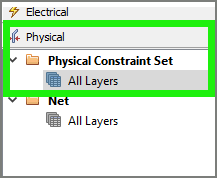

- In the Design Workflow, select Constraints > Physical.

Note: This opens the constraint manager window. In the constraint manager, you can assign electrical, physical, and spacing constraints. Assign constraints by creating Csets or assigning values to each individual net.

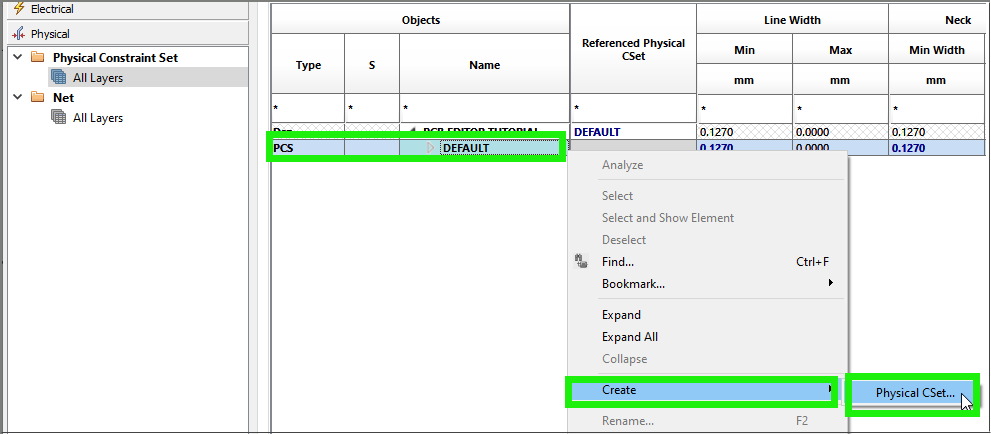

- In the constraint manager window, select the Physical Constraint Set > All Layers.

- Right click and select Create > Physical CSet.

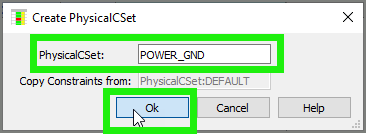

- Name the constraint set POWER_GND and click OK.

- Set the following constraint values:

- Minimum line width: 0.381

- Minimum neck width: 0.127

- Maximum neck length: 5.08

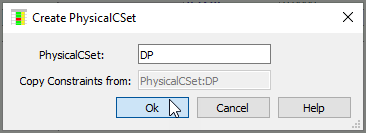

- Right click and select Create> Physical CSet.

- Name the constraint set DP and click OK.

- Set the following constraint values:

- Line Width: 0.127

- Primary Gap: 0.127

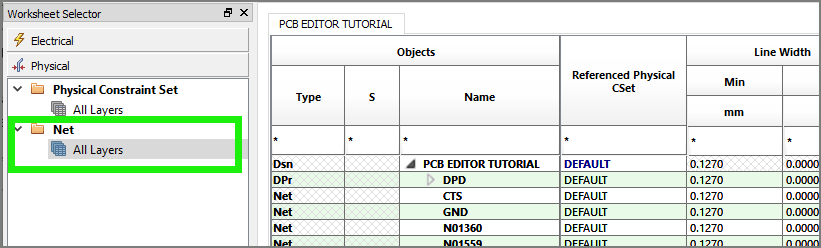

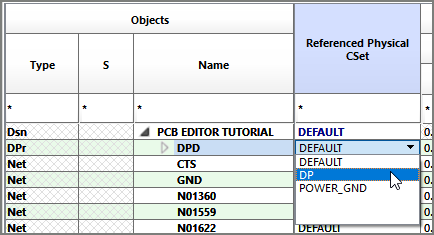

- In the worksheet selector, select Net > All Layers.

- In the Referenced Physical CSet column, assign the POWER_GND CSet to 3.3V and GND.

- In the Referenced Physical CSet column, assign the DP CSet to DPD.

Note: Assign the differential pair Cset (DP) at the top level to apply to each net.

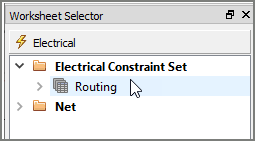

- In the worksheet selector, select Electrical > Electrical Constraint Set > Routing.

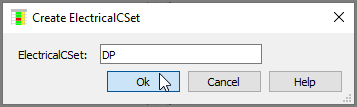

- Right click and select Create > Electrical CSet.

- Name the CSet DP and click OK.

- Set the following constraint values:

- Gather Control: Ignore

- Uncoupled Length: 5.08

- Static Phase Tolerance: 0.508

- In the Worksheet Selector, select Net > Routing > Differential Pair.

- In the Referenced Electrical CSet column, assign the DP Cset to DPD.

- In the Worksheet Selector, select Properties > Net > General Properties.

- Assign 0 to GND.

- Assign 3.3 to 3.3V.

- Close the Constraint Manager Window.