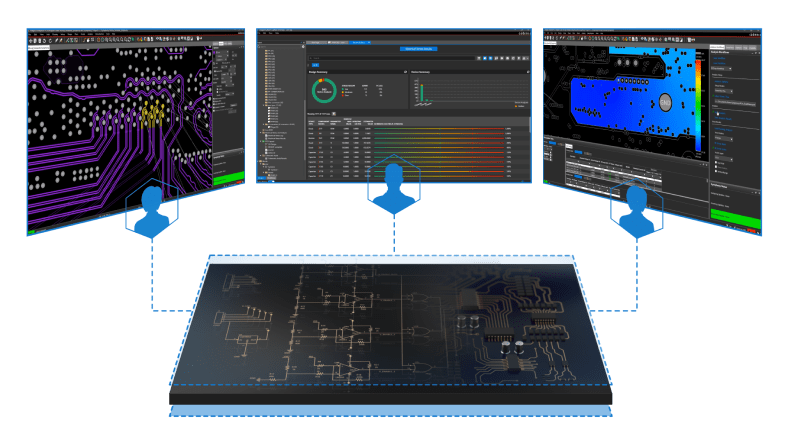

Streamline your PCB and system design with a single, cohesive environment for schematic design, electrical analysis, PCB design, signal and power integrity analysis, design data management, and more.

Get your designs completed in record time with best-in-class layout and routing engines.

Built to scale, seamlessly leveraging the latest multithreading and distributed computing technologies.

Ensure prep for manufacturing is a simple sign-off step not a long find-fix-repeat process with integrated simulation, DFM, and constraint management engines.

Your design flows and requirements are unique. The Allegro Platform allows you to build automation for your unique requirements on top as needed.

Reduce SI issues while routing to maximize performance and functionality with advanced high-speed capabilities in Allegro X. Auto-interactive delay and phase tune, automatic rules-based routing, timing vision with color-coded results, backdrilling support, and reusable electrical rules sets lets you quickly and successfully complete your high-speed designs.

Achieve first-pass manufacturing success by verifying the PCB design against manufacturer’s rules and capabilities during the PCB layout with integrated design for manufacturing (DFM) rules. The DesignTrue DFM Partner Portal and DesignTrue DFM Wizard allow engineers to quickly configure fabrication, assembly, and test constraints based on requirements direct from manufacturers to guarantee a producible, error-free PCB.

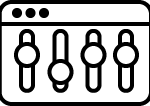

Allegro X offers a PCB design solution for the automotive industry with a comprehensive set of features to address the stringent requirements of vehicle electronics. Excelling in areas like reliability, requirement management, and support for automotive-specific standards. Advanced simulation and analysis are available at all stages of design to ensure optimal performance and durability in challenging automotive environments.

Automotive Standards Compliance: Allegro X is fully ISO 26262 compliant to eliminate risk and uncertainty into your design process while helping you meet standards like AEC-Q100, enabling designers to adhere to safety and reliability guidelines.

Component Libraries: Allegro X includes access to rich and up-to-date library of automotive-grade components thought partnerships with Ultra Librarian and others. Robust library creation tools allow teams to quickly build and modify parts to their specifications simplifies design and ensures compatibility with automotive-specific components.

Simulation and Analysis: Simulation and analysis capabilities for thermal management, signal integrity, and electromagnetic compatibility (EMC)

are built directly into the design flow to allow comprehensive and early analysis of designs to ensure they can withstand harsh automotive conditions.

Collaboration & Traceability: Easily collaborate on designs in real-time, track changes and management requirements all in the context of your design environment.

Integration with ECAD/MCAD: Allegro X provides Seamless integration with mechanical design tools (MCAD) such as SOLIDWORKS, CATIA, NX, and more to ensure proper fitting of PCBs into the automotive chassis and aids in the overall design process, promoting synergy between electronic and mechanical components in vehicles.

Allegro X enables designers building consumer electronics to provide cutting edge solutions in short periods of time to meet the demands of fast-paced product development cycles.

Allegro X provides those designing medical devices, a platform that prioritizes precision, reliability, and compliance with industry regulations. Allegro offers specialized features to ensure the safe and accurate functioning of medical devices while facilitating the development process for medical device manufacturers.

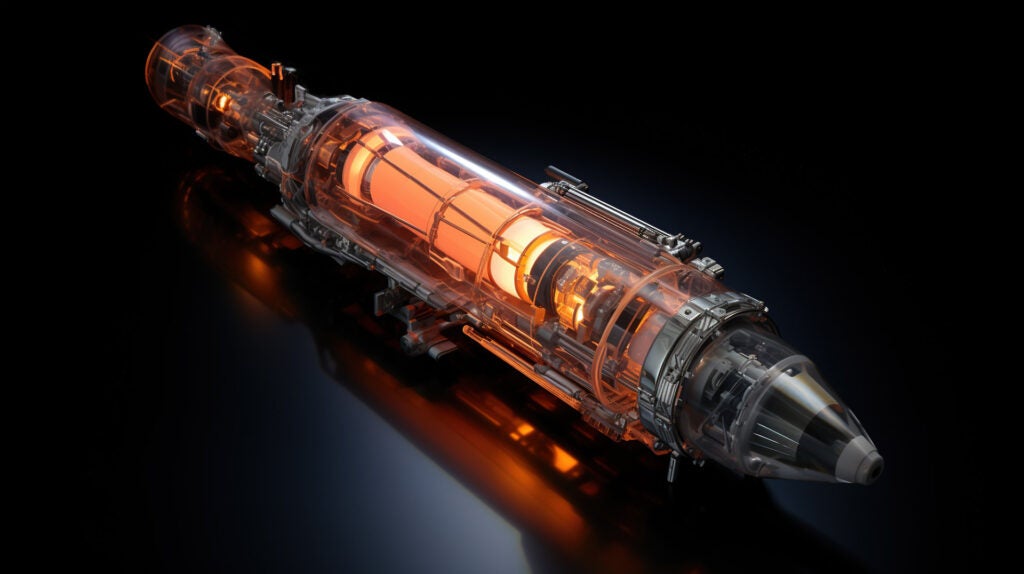

Allegro X offers a comprehensive suite of features tailored to meet the exacting demands of military & aerospace applications. With a priority on reliability, stringent compliance with military standards, advanced simulation capabilities, and security protocols to ensure the seamless development of electronic systems for critical applications.

In the industrial sector, a PCB design CAD tool must provide a feature set tailored to address the specific demands of industrial applications. It should emphasize reliability, compliance with industry standards, advanced simulation capabilities, and support for secure collaboration to enable the efficient development of electronic systems for rugged and mission-critical environments.