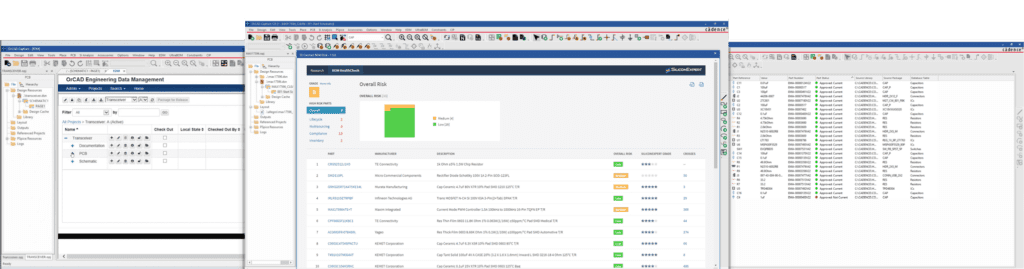

File and Library Management

Easily manage symbol and footprint libraries, design data, and documentation to create data consistency for your entire team. Design validation and automatic packaging of your manufacturing data ensures the correct revision of your design can be produced the first time.