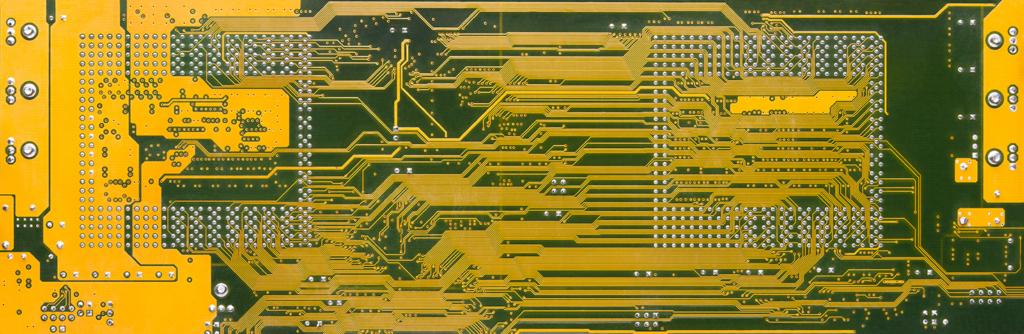

High-Density Interconnect (HDI) routing is a PCB design technique used to create boards with a high density of components and interconnections. HDI routing enables the placement of more components in a smaller area, making it popular for applications that demand compact, lightweight, and high-performance designs, such as smartphones, tablets, medical devices, and high-speed computing equipment. HDI routing utilizes a combination of microvias, blind and buried vias, laser-drilled vias, and sequential layers to create high-density, high-performance PCB layouts that are essential in modern electronic devices. HDI boards are more intricate, requiring careful planning to manage small trace widths, tight spacing, high via densities, and manufacturing complexities.

Let our team help you craft the perfect PCB design solution for your requirements. Contact us for more information.