Managing PCB Bills of Materials (BOMs) effectively determines whether your electronic product launches on time and within budget. Poor BOM management leads to cost overruns, low-quality board builds, and manufacturing delays that can derail entire projects. Overcoming current challenges, like component shortages and long turnaround times, makes it imperative to incorporate supply chain resilience into your PCB BOM management.

Best Practices for Resilient PCB BOM Management

The PCB BOM is critical to accurately bring your board design to life. However, your BOM is much more than a listing of all of the components used on your circuit board. In fact, the BOM should include detailed information to ensure procurement and help your CM execute efficient high-yield board spins. To accomplish this, your BOM should be created by following best practices that take into account supply chain issues that could increase the risk of project delay or increase the cost of development of your PCBs in the future. The list, shown below, also highlights where and to what extent automation or AI tools can be leveraged to maximize efficiency.

| Resilient PCB BOM Management Best Practices | ||||

| BOM Element | Best Practice | Risk Level | Automation Priority | Cost Impact |

| Part Numbers | Manufacturer + Internal | Critical | High | 20-40% |

| Component Status | Active/NRND/Obsolete | High | High | 15-25% |

| Alternate Parts | 2+ per critical component | Medium | Medium | 10-20% |

| Pricing Data | Real-time supplier feeds | Medium | High | 5-15% |

| Inventory Levels | Real-time stock monitoring | High | High | 10-30% |

| Lead Times | Dynamic supplier data | Critical | High | 25-50% |

| Package Types | Standardized library | Low | Low | 2-5% |

| Tolerance Specs | Automated validation | Medium | Medium | 5-10% |

| Compliance Data | RoHS/REACH tracking | Critical | High | Regulatory |

| Lifecycle Stage | Proactive monitoring | High | High | 20-40% |

| Supplier Rating | Performance metrics | Medium | Medium | 5-15% |

| Minimum Order Quantity (MOQ) Requirements | Order optimization | Medium | Medium | 10-25% |

| Geographic Sourcing | Multi-region strategy | High | Low | 15-30% |

| Quality Ratings | Supplier scorecards | Medium | Medium | 5-20% |

| Environmental Data | Temperature/humidity specs | Low | Low | 2-8% |

| Documentation Links | Datasheets/CAD models | Low | High | Time savings |

A comprehensive BOM that incorporates supply chain resilience should include most of the elements listed above. Doing so will help you ensure your boards are manufactured efficiently and your design is optimized for resiliency. Managing your PCB BOM is an ongoing process, as several challenges may arise throughout development and even once your board is in production.

PCB BOM Management Challenges

Successful PCBs may remain on the market for many years, even decades. Throughout this time, changes to your BOM can have a significant impact on manufacturing or production. The same is true for development, where your design is finalized. Changes that can translate into major challenges, such as component obsolescence, are listed in the table below along with their impact and best practices to avoid them.

| Critical PCB BOM Management Challenges | |||

| Challenges | Root Causes | Product Impact | Best Practice to Avoid |

| Component Obsolescence | Parts discontinued mid-design | 6-12 week delays | Lifecycle monitoring |

| Pricing Volatility | Material costs fluctuate 20-50% | Budget overruns | Dynamic pricing feeds |

| Supply Chain Disruption | Components unavailable | Production stops | Multi-supplier strategy |

| Version Control Errors | Outdated BOMs in production | Quality issues | Automated synchronization |

| Manual Data Entry | Human errors in part specs | Rework costs | Database integration |

| Lack of Standardization | Inconsistent part libraries | Design inefficiency | Component libraries |

The probability of facing one of the challenges above increases with design complexity and the number of unique components. However, less complex PCBs are also vulnerable, and the impact is similar. Therefore, it is important to follow resilient PCB BOM management best practices for all of your designs.

Component Lifecycle Tracking

One of the most effective means of managing changes to your BOM is component lifecycle tracking. It is common to check component status prior to selection; however, projected lifecycles may change. For example, the component manufacturer may develop an alternative that improves performance or lowers cost.

In these situations, the component status may be changed to not recommended for new design (NRND). Depending on whether the original component is slated for reduced production or obsolescence and when it may be necessary to update your BOM and/or design, it may be best to continue to use the original component or make the switch. By ensuring that component status updates are tracked and you are alerted, interruptions in product delivery can be avoided.

BOM Cost Optimization and Supplier Management

In addition to real-time monitoring, it is also essential to diversify your supplier network and institute good cost optimization guidelines. Strategic cost optimization requires balancing component performance, availability, and price across multiple suppliers. Effective supplier management creates competitive pricing while ensuring supply chain resilience. Effective cost optimization strategies to implement include the following.

| PCB BOM Management Cost Optimization Strategies | |||

| Strategy | Potential Savings | Implementation Complexity | Risk Level |

| Volume Consolidation | 15-25% | Low | Low |

| Alternative Sourcing | 10-20% | Medium | Medium |

| Standardization Programs | 20-35% | High | Low |

| Supplier Negotiations | 5-15% | Medium | Low |

| Market Timing | 10-30% | High | High |

| Design Value Engineering | 25-50% | Very High | Medium |

Advanced BOM Analytics and Reporting

Modern BOM management systems provide analytics capabilities that transform component data into actionable business intelligence. Advanced reporting enables proactive decision-making and continuous process improvement. Some key performance indicators to monitor are:

| PCB BOM Management KPIs | |||

| Metric Category | Specific KPIs | Target Range | Business Impact |

| Cost Management | BOM cost variance | ±5% | Budget control |

| Supply Chain | Component availability | >95% | Schedule adherence |

| Quality | BOM accuracy rate | >99% | Manufacturing efficiency |

| Process | BOM generation time | <2 hours | Design velocity |

| Compliance | Regulatory conformance | 100% | Market access |

| Innovation | New component adoption | 10-15% annually | Competitive advantage |

With the uncertainty surrounding components in the electronics industry today, it is imperative that you prioritize supply chain resilience. Optimizing this implementation requires instituting a similar strategy to your PCB BOM management, where component availability and cost are major drivers of the components to choose to use in your design.

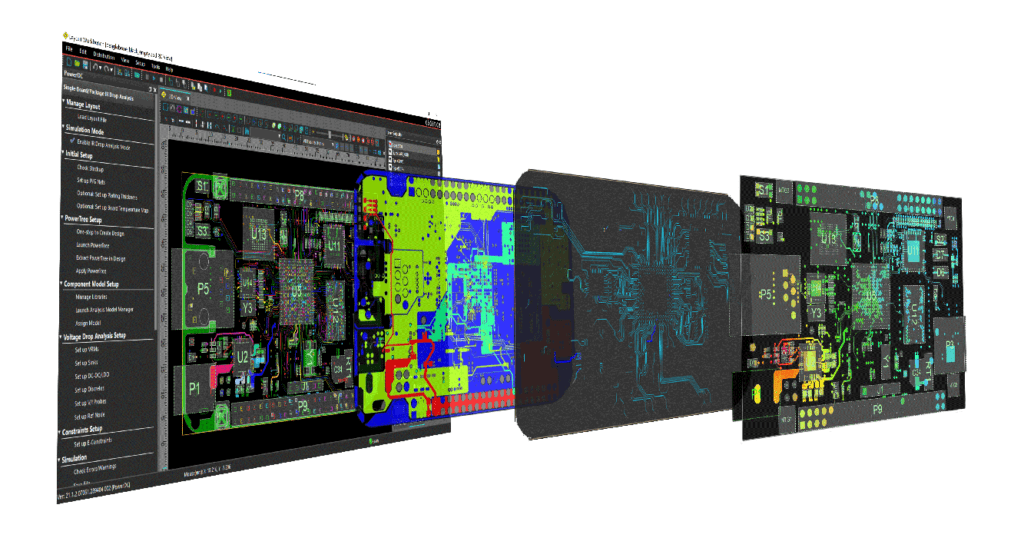

Your EDA tool likely includes a BOM generator. However, the features and/or capabilities that emphasize resilience may not be included. Therefore, it may be necessary to augment your BOM management capabilities by following best practices, as we’ve discussed here, and/or implementing software support. In either case, the best option is to look to the industry leader in supporting engineers with the software tools and learning resources necessary to optimize their PCB design workflow.