High power electronics product development faces unprecedented thermal challenges as modern designs pack more power into increasingly compact form factors. For circuit boards, thermal management solutions have evolved from simply adding heat sinks to high power components. Today, an in-depth understanding of causes and impacts is required to devise a successful plan of thermal management in high power electronics to address heat distribution and dissipation.

The Impact of Thermal Management

Thermal problems on your board and/or in your electronics-based system may be caused by fault modes, such as shorts, an unstable power distribution network (PDN), or issues such as surface tracking. However, excess heat is more commonly generated from normal high power device operation and inadequate distribution and dissipation techniques. In either case, optimizing thermal management in high power electronics is a design issue that can only be achieved by first understanding the range of impact.

| The Actual Impact of Thermal Management in High Power Electronics | |||

| Impact Area | Ineffective Thermal Management | Optimal Thermal Management | Performance Improvement |

| Component Reliability | 50-70% reduction in lifespan | Extended operational life | Up to 300% increase¹ |

| System Efficiency | 15-25% power loss to heat | Maintained peak performance | 85-95% efficiency retention¹ |

| Failure Rate | Exponential increase with temperature | Controlled failure rates | 50-80% reduction¹ |

| Operating Temperature | 150-250°C peak temperatures | 30-80°C controlled range | 60-70% temperature reduction² |

| Energy Consumption | Higher cooling demands | Optimized power usage | 20-40% energy savings¹ |

| Maintenance Costs | Frequent component replacement | Reduced downtime | 40-60% cost reduction¹ |

Thermal management in high power electronics directly impacts three fundamental design elements that determine system success: reliability, efficiency, and longevity. As power densities continue to increase, these factors become even more interdependent.

- Reliability Impact:

Modern power electronics operating without proper thermal management experience failure rates that can be ten times higher than those of properly cooled systems. - Efficiency Impact:

High temperatures increase resistance and switching losses, creating a destructive cycle where poor thermal management leads to more heat generation. - Longevity Impact:

Semiconductor lifetime reduces exponentially with elevated junction temperatures, making thermal control essential for consistent performance.

These impacts necessitate that optimized thermal distribution and dissipation strategies be implemented as a critical aspect of your PCB design process.

Thermal Distribution and Dissipation Optimization Strategies

Thermal management in high power electronics requires considering heat distribution and dissipation for your board and the system it operates within. Consequently, your optimization plan must address the unique challenges of PCB high power design, as well as system-level concerns like enclosure cooling. Strategies to successfully meet these mandates are listed below.

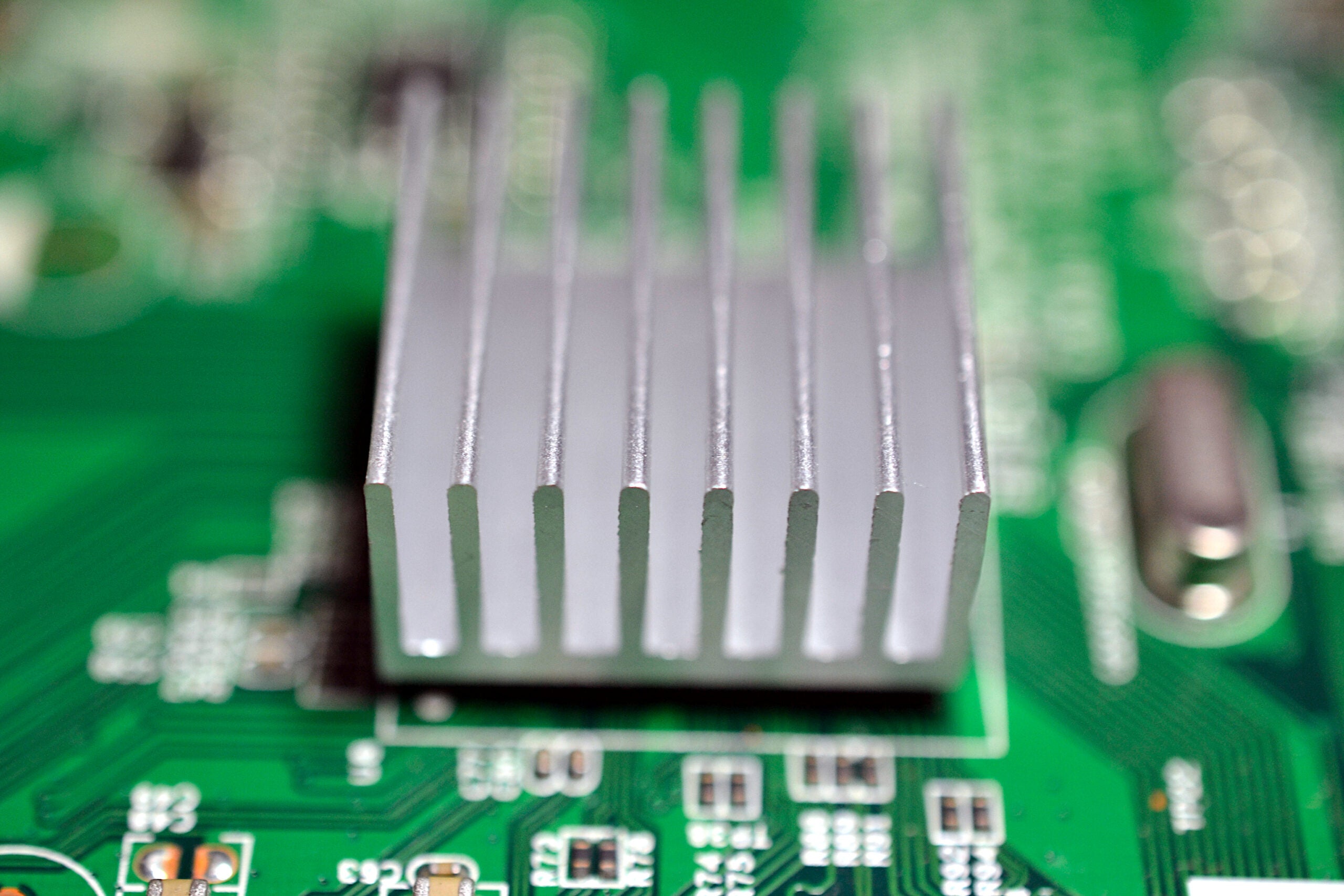

How to Optimize Thermal Management in High Power Electronics ✅Increase copper thickness to 2-4 oz in high-current areas for improved heat spreading ✅Implement thermal via arrays with 0.2-0.3mm diameter vias spaced 0.5-1.0mm apart ✅Position high power components near board edges for enhanced airflow access ✅Use thermal interface materials with >3 W/m·K conductivity with component heat sinks ✅Use heat sinks with fin spacing (2-4mm) to maximize surface area and promote airflow ✅Integrate temperature sensors for real-time monitoring and dynamic thermal management ✅Apply copper pours on multiple layers to create thermal planes for heat distribution ✅Select materials like aluminum nitride or copper-core substrates for critical applications ✅Implement forced convection with targeted airflow over hot spots ✅Utilize liquid cooling for power densities exceeding 100W/cm² ✅Design thermal relief patterns carefully to balance electrical and thermal requirements ✅Consider component placement to avoid creating thermal hot spots and interference ✅Implement thermal simulation to analyze and verify heat distribution and dissipation results |

Employing these design strategies will help you optimize your thermal management solution. However, effectively applying them and verifying their impact for your specific project requires employing the right software solutions, including the best thermal simulation software tools. The best option is to partner with the industry leader for equipping engineers with the software and support they need to optimize their PCB designs.

EMA Design Automation is a leading provider of the resources that engineers rely on to accelerate innovation. We provide solutions that include PCB design and analysis packages, custom integration software, engineering expertise, and a comprehensive academy of learning and training materials, which enable you to create more efficiently. For more information on optimizing your thermal management in high power electronics solutions and how we can help you or your team innovate faster, contact us.

Sources

- EMA Design Automation. “Best High Power PCB Design Guidelines.” https://www.ema-eda.com/ema-resources/blog/best-high power-pcb-design-guidelines-emd/

- Jebelli, A., et al. “Advanced Thermal Management for high power ICs: Optimizing Heatsink and Airflow Design.” Applied Sciences, 2024. https://www.mdpi.com/2076-3417/14/20/9406

- Power Electronics News. “Future Trends in Thermal Management for Power Electronics.” https://www.powerelectronicsnews.com/thermal-management/

- LinkedIn Engineering Analysis. “Thermal Management in Power Electronics PCB.” https://www.linkedin.com/pulse/thermal-management-power-electronics-pcb-vathc