“The OrCAD tools helped us find problems early in the design phase, instead of the testing phase. They saved us a lot of debugging time and money in the end.”

Remi Jonkman, Electrical Engineer

Company: Electric Superbike Twente | Industry: Automotive and Motorsport | Solution: OrCAD X, PSpice

About Electronic Superbike Twente

Founded in 2017, Electric Superbike Twente is a student-led engineering team from the University of Twente. The team was created to give students hands-on experience designing and building a competitive electric superbike. Their mission was to prove that electric motorcycles can be just as exciting and high-performing as traditional petrol-powered bikes and to compete at the highest level in European electric motorcycle racing.

Goals

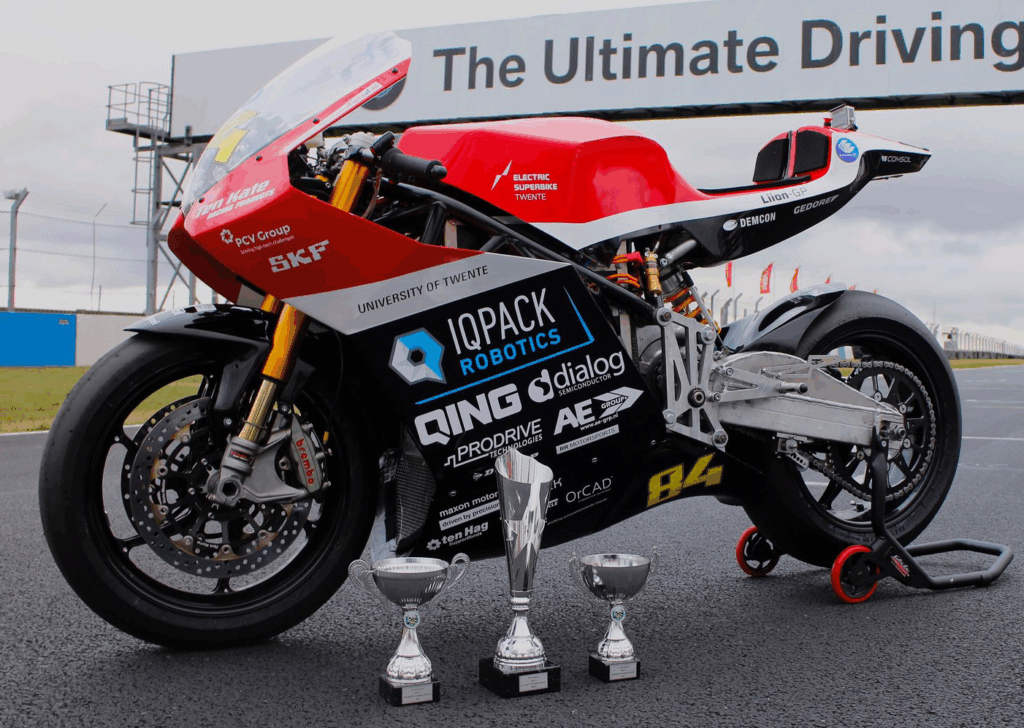

The Electric Superbike Twente Team was tasked with designing an electric superbike to race in and win the European MotoE Competition in only 9 months. The design needed to include a 100kW electric motor system with a custom automotive-compliant control unit that could safely handle high voltages, high currents, and extreme speeds. The Electric Superbike Twente Team had the following goals:

- Design and build a competitive electric superbike within nine months

- Achieve automotive-grade safety and compliance

- Minimize physical prototyping through first-time-right design

- Successfully compete in the European MotoE Championship

With the short deadline and complex design, the team faced several challenges that needed to be addressed to achieve success.

Challenges

The Electric Superbike Twente team faced a highly aggressive timeline combined with significant technical complexity. Due to this, some of the challenges seen throughout the design process include:

Complex Custom Design

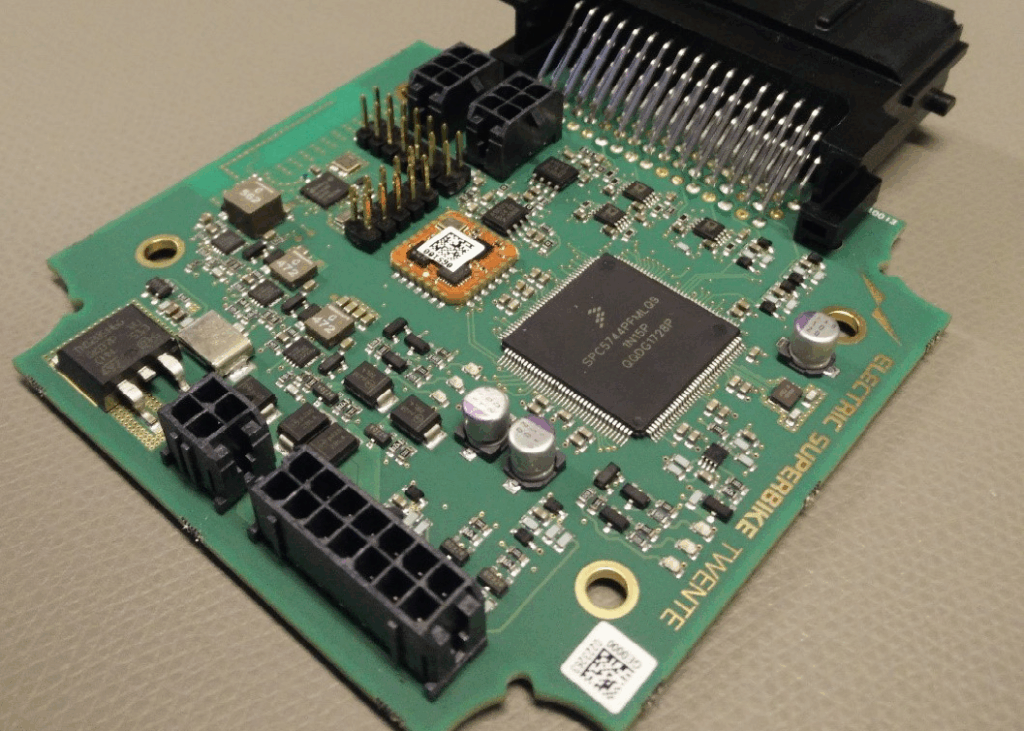

The electric superbike design required a custom-made control unit incorporating only automotive-grade parts. In addition, redundant software execution was required to make sure the control unit made the right choices and wasn’t fooled.

Signal Integrity Concerns

The 100kW motor driven by an 8kHz PWM produced a lot of electromagnetic interference (EMI). This noise was negatively impacting sensor readings. Careful filter design was required at each sensor input to cancel out noise and ensure the control unit made the right decision.

Power Integrity Concerns

The bike’s power is delivered through several lithium-ion batteries that can become unstable if not properly managed.

Time Constraints

With only nine months to complete development there was no time for multiple hardware iterations, a “first-time right” design approach was critical.

Facing these extreme technical and safety challenges, the team leveraged OrCAD X and PSpice to virtually prototype, validate, and implement a complex automotive-grade control system. The result was a reliable, safe, and championship-winning electric superbike, completed on time and on the first design pass.

Results

By leveraging OrCAD X and PSpice, Electric Superbike Twente Team completed their design on time with first-time-right accuracy. The final superbike proved to be reliable, safe, and exceptionally fast, delivering 1000Nm (737 ft-lbf) of torque at the rear wheel and achieving massive accelerations times. The success of their design was aided in selecting the right tools for the design process:

Schematic Design

The Electric Superbike Twente Team selected OrCAD X Capture, a well-known schematic entry tool which increased their productivity quickly. OrCAD X Capture products offered an extensive, pre-configured model library to accelerate the schematic creation process, providing access to verified symbols, footprints, and 3D models. In addition, the tight integration with PSpice allowed the design team to perform virtual prototyping to identify and resolve potential failures early in the design phase.

Simulation

Powerful PSpice simulation technology helped the Electric Superbike Twente Team analyze critical circuitry, identify potential problems, and correct issues before moving to the PCB layout. For example, they designed an overvoltage protection unit from scratch to ensure the power cutoff is quick and safe when overvoltage occurs. which saved the other design circuitry many times. This saved the team both time and costs without sacrificing quality.

PCB Design

With the OrCAD X flow, the Electric Superbike Twente Team was able to move quickly from the design and analysis phase to the implementation phase. Custom PCBs capable of handling up to 250A at 592V were developed using OrCAD X PCB Editor. The team leveraged constraint management to ensure safety and complex design requirements such as proper creepage distances, clearances, and track widths. 3D STEP models were used to verify PCB footprint accuracy as well as mechanical fit and enclosure compatibility, allowing the team to transition efficiently and confidently from design to manufacturing.

In their first year of competition, the team became European MotoE Champions, demonstrating how advanced design and simulation tools can turn ambitious ideas into championship-winning results.

“Thanks to the OrCAD complete software package, it is possible to create schematics and PCBs on the go. This is essential for the development of prototypes and different iterations.”

Jeroen Goudswaard, Head of Powertrain & PR

By leveraging OrCAD X and PSpice in their development process, the Electric Superbike Twente Team was able to:

- Achieve first-time-right design accuracy under an aggressive nine-month deadline

- Deliver a reliable, safe, and high-performance electric superbike

- Produce 1000Nm of torque at the rear wheel, enabling exceptional acceleration

- Win the European MotoE Championship in their first year of competition

- Reduced development time, debugging effort, and overall cost through virtual prototyping

Learn more about how Electric Superbike Twente leveraged the capabilities of OrCAD X to achieve first-time-right design and MotoE champion success with the full story here.