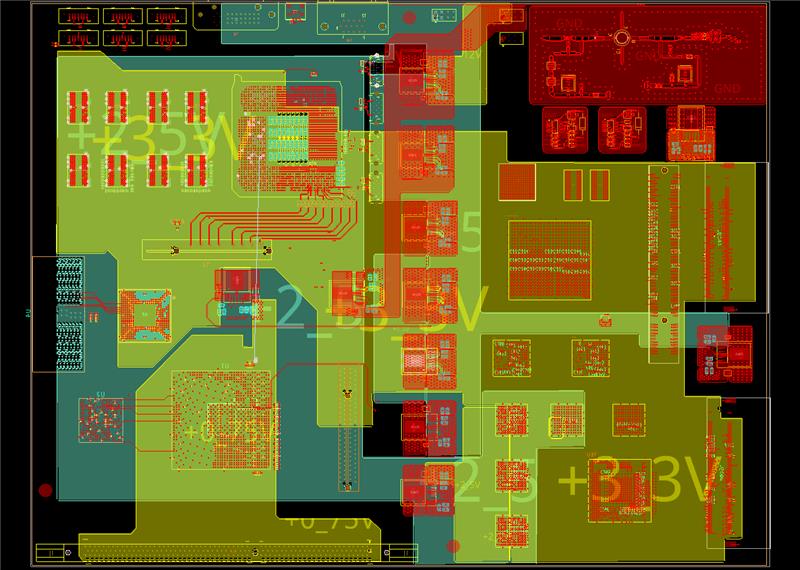

High-current and high-power PCB designs are specialized printed circuit boards engineered to handle large amounts of current, typically used in applications that require the delivery of significant power. These designs are common in power electronics, automotive systems, industrial machinery, and electric vehicles, where components may need to manage currents ranging from several amps to hundreds of amps without overheating, experiencing excessive voltage drop, or compromising performance. High-current PCB designs require specialized techniques to handle significant current loads safely and efficiently. These designs incorporate thicker copper, wider traces, effective thermal management, and strategic layout to maintain functionality under demanding conditions, which is vital for applications in power-intensive industries.

Let our team help you craft the perfect PCB design solution for your requirements. Contact us for more information.