Company: Solid State Logic | Industry: Audio | Solution: OrCAD X and PSpice

“We’re very optimistic about our future and, with our scalable Cadence circuit simulation and design tool flow with OrCAD Capture CIS with PSpice and Allegro PCB Designer tools, we have an environment that will grow with us.”

— Glen Pratley, Hardware Design Team Leader, Solid State Logic

About Solid State Logic

Founded in 1969 and headquartered in Oxfordshire, UK, Solid State Logic (SSL) is a global leader in professional audio innovation. The company designs and manufactures analog and digital mixing consoles used in studio recording, live sound production, and broadcast environments. SSL products are known for exceptional sound quality and engineering precision, with complex sub-circuits, such as microphone preamplifiers, often consisting of up to 100 discrete components that drive product differentiation.

Goals

Solid State Logic aims to continuously innovate while maintaining the premium sound quality its customers expect. With long product lifecycles but frequent feature updates, the engineering team is responsible for keeping products competitive and relevant. The company also aligns product launches with major industry trade shows, making speed, accuracy, and predictability in development critical to capturing market opportunities.

Challenges

Meeting aggressive deadlines while ensuring uncompromised audio performance presented significant engineering challenges for Solid State Logic:

Design Complexity

Many of their designs are complex analog and mixed-signal systems, including microphone preamplifiers with up to 100 discrete components per channel.

Aggressive Timelines

Typically, the company launches new products at tradeshows, so they can’t miss these market opportunities.

“We can’t afford the extra time of lots of board respins. And, it’s important that our tools remain relevant and useful, since we can’t afford to keep changing the tools.”

- Charles Pickers, Senior Hardware Engineer, Solid State Logic

Solid State Logic’s hardware team (responsible for hardware design, firmware, and PCB layout) could not afford multiple board respins or extended validation cycles.

Operating Conditions

Additionally, products often operate in extreme environments, such as outdoor concerts in hot and humid conditions, requiring rigorous validation under varying environmental scenarios.

Their legacy CAD tools lacked the scalability and advanced simulation capabilities needed to support these demands efficiently, so Solid State Logic turned to OrCAD X.

Results

By migrating to the OrCAD X and PSpice design flow, Solid State Logic achieved first-time-right design accuracy, dramatically reducing risk before committing designs to manufacturing.

OrCAD X Capture CIS

With OrCAD X Capture CIS, Solid State Logic was able to build a large library of components and reference designs. For component management, this library aligned the team on component selection accelerating their design process and controlling costs. A library of reference designs created a catalog of their work enabling the team to speed up the design process for new and upgraded products, with cut and paste methods and reusing known-good circuitry and IP.

Additionally, OrCAD X Capture CIS includes the ability to create hierarchical designs. This coupled with PSpice simulation allowed Solid State Logic to model blocks of circuitry and the corresponding circuit characteristics and compare blocks of similar circuitry.

PSpice

“PSpice Designer does everything that we need and it is scalable, providing everything from low-end seats for tasks like placement and viewing to higher level tools for the heavier lifting of circuit design. With PSpice technology, we can mitigate many design risks before committing to copper.”

— Glen Pratley, Hardware Design Team Leader, Solid State Logic

PSpice includes advanced circuit simulation capabilities allowing the team to model and benchmark circuit performance. Solid State Logic used the hierarchical design capabilities of OrCAD X Capture CIS coupled with PSpice to model microphone preamplifier circuits which can have up to 100 discrete components for a single channel. Using this capability, they evaluated circuit characteristics, create a copy of the circuitry in another hierarchical block, modified the circuit and then compared the modified circuit to the original as a benchmark.

Solid State Logic’s products must operate in extreme environmental conditions, for example an outdoor concert on a hot humid day. To ensure circuit functionality during these extreme conditions, PSpice was used to simulate circuit behavior over a range of extreme temperatures to identify required circuit and component modifications.

Additionally, PSpice includes access to a large library of vendor-supplied SPICE models, eliminating the need to create complex simulation models internally, saving weeks to months per design.

“With the majority of IC vendors providing PSpice simulation models, we’ve never had to create our own simulation models. This has helped improve our productivity, saving us weeks to several months since we don’t have to create any complex simulation models ourselves.”

— Glen Pratley, Hardware Design Team Leader, Solid State Logic

The integration of PSpice in the PCB design flow helps Solid State Logic analyze circuit behavior upfront and mitigate potential failures early in the design cycle.

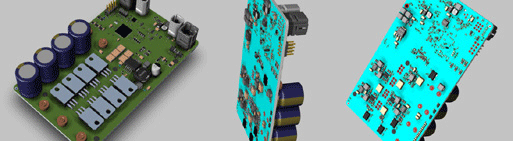

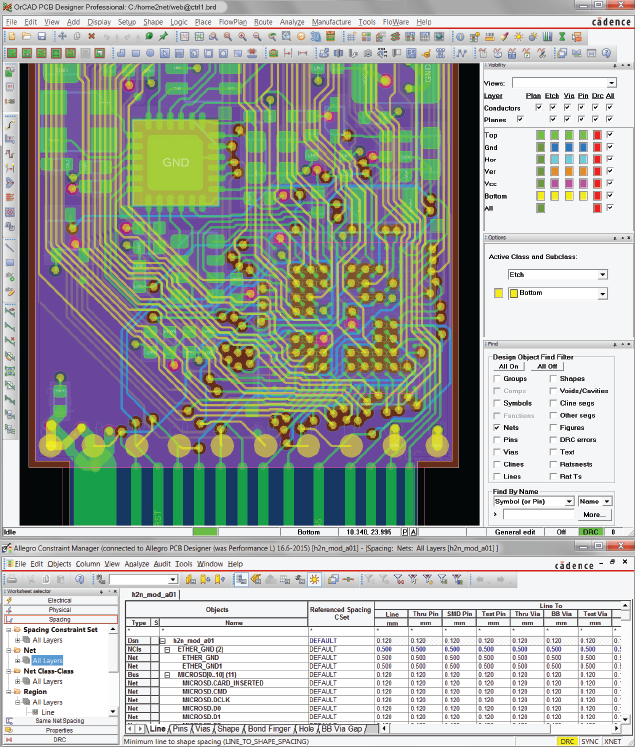

Allegro X PCB Designer

Allegro X PCB Designer accelerated the PCB layout process with advanced features, such as automatic management of copper planes and pours. Eliminating manual tasks with automation enabled the Solid State Logic team to support a product cycle with frequent updates and aggressive time-to-market goals.

Sigrity SI

Solid State Logic leveraged the capabilities in Sigrity SI to perform topology extraction for signal and power integrity assessment and improve product performance during the PCB design process.

“We’re very optimistic about our future and, with our scalable Cadence circuit simulation and design tool flow with OrCAD Capture CIS with PSpice and Allegro PCB Designer tools, we have an environment that will grow with us”.

– Glen Pratley, Hardware Design Team Leader, Solid State Logic

The integrated workflow also streamlined PCB layout, improved component management, accelerated development timelines, and enabled Solid State Logic to release new products and upgrades quickly, ultimately strengthening their ability to capture market opportunities while maintaining superior sound quality. Learn more about how Solid State Logic accelerated the PCB design process using OrCAD’s integrated environment for schematic capture, simulation, and PCB layout here.