The biggest threat to electronics project success is typically assumed to be getting the board to work as envisioned or defined. However, managing costs may be more impactful in the bigger picture. Irrespective of how good the product is functionally, projected profitably, and return on investment (ROI) are key factors that drive its development. If the board cannot be developed and produced within its budget, it likely will not be done.

For PCB designers and engineers, optimizing process efficiency is always an important objective. The level of success achieved here will be directly proportional to successfully managing overall project costs and is foundational to developing and executing engineering cost reduction strategies that work.

Best Engineering Cost Reduction Strategies for 2025

Developing engineering products, especially electronic circuit boards, is usually bound by costs. More specifically, engineering products are undertaken with the expectation of not only serving an end-user need or demand, but also being profitable. Consequently, engineers who define the components and materials to be used must strike a balance between quality and cost. In most cases, the desired costs will exceed the level that best achieves this balance. The actions taken to restore the balance, maximizing ROI and profitability, can collectively be called engineering cost reduction strategies. The best of these for 2025 are listed below.

| Best Engineering Cost Reduction Strategies and Impact | ||||

| Cost Reduction Strategy | Development Cycle Stage | Cost Benefits | Potential Savings | Project Risk |

| Investigate Alternative Components | Design |

|

20-30% | Medium |

| Maintain an Optimized Component Library | Design |

|

Up to 20% | Low |

| Establish a Resilient Supply Chain | Design |

|

10-20% | Medium |

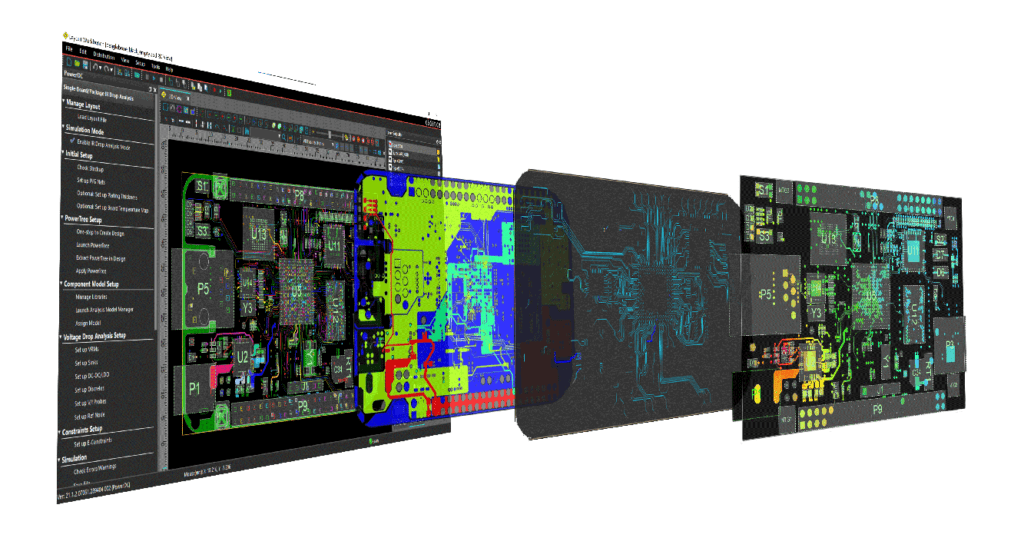

| Leverage Automation | Design |

|

30% or more | Low |

| Employ Simulation Verification | Design |

|

Up to $10k or more, depending on the project | Low |

| Volume Consolidation | Procurement |

|

15-25% | Low |

| Diversify Your Distribution Channel Network | Procurement |

|

Varies | Low |

| Quality Management System (QMS) | Entire Process |

|

20-30% | Low |

| Supplier Negotiation | Procurement |

|

5-15% | Low |

| Regional Optimization | Procurement and Manufacturing |

|

5-15% | Medium |

| Collaborate with Contract Manufacturer (CM) | Manufacturing |

|

10-50% | Low |

| Digitize Processes | Entire Process |

|

10-50% depending on the development stage | Medium |

| Minimize Physical Testing | Testing |

|

Up to 50% | Low |

As shown above, significant savings can be realized by employing proven engineering cost reduction strategies. These savings can be categorized as direct or indirect.

Direct Engineering Cost Savings 💲Lower prices for components 💲Lower board material costs 💲Lower manufacturing costs 💲Lower shipping costs 💲Lower board verification test costs |

Indirect Engineering Cost Savings 🕤Less time spent researching components 🕤Less time spent designing your PCB layout 🕤Faster manufacturing turnaround time 🕤Less time spent on board redesign and revisions 🕤Less time spent on manual processes and on correcting errors from manual processes |

Engineers and PCB designers have the most control over component costs. As shown above, several cost reduction strategies can be implemented to better control the direct and indirect costs associated with the components selected. The single most important means of managing component-related costs in 2025 is to build a resilient supply chain.

PCB Design for Supply Chain Resilience

Supply chain resilience can be defined as the strategies and actions put in place to ensure that the components used in a design are available in the quality and quantity required when needed. Due to the ongoing challenge to reliably source components over the past several years because of shortages, component price volatility, and an uncertain trade future due to fluctuating tariffs, incorporating supply chain resilience into the PCB design process has become critical. Failing to do so may result in higher prices for components and materials, extended board redesign time when the primary choice is not available, longer turnaround time for manufacturing, and higher manufacturing costs. Many of these issues can be minimized, if not avoided entirely, by implementing key design for resilience methodologies, as listed below.

Design-for-Resilience Methodologies

- Component Selection with Supply Chain Intelligence

Modern PCB design requires integrating supply chain data directly into component selection workflows. This means having real-time access to:

- Current inventory levels across multiple suppliers

- Lead time forecasts based on historical data and market conditions

- Price trending information to optimize cost timing

- Risk assessments, including supplier financial health and geographic factors

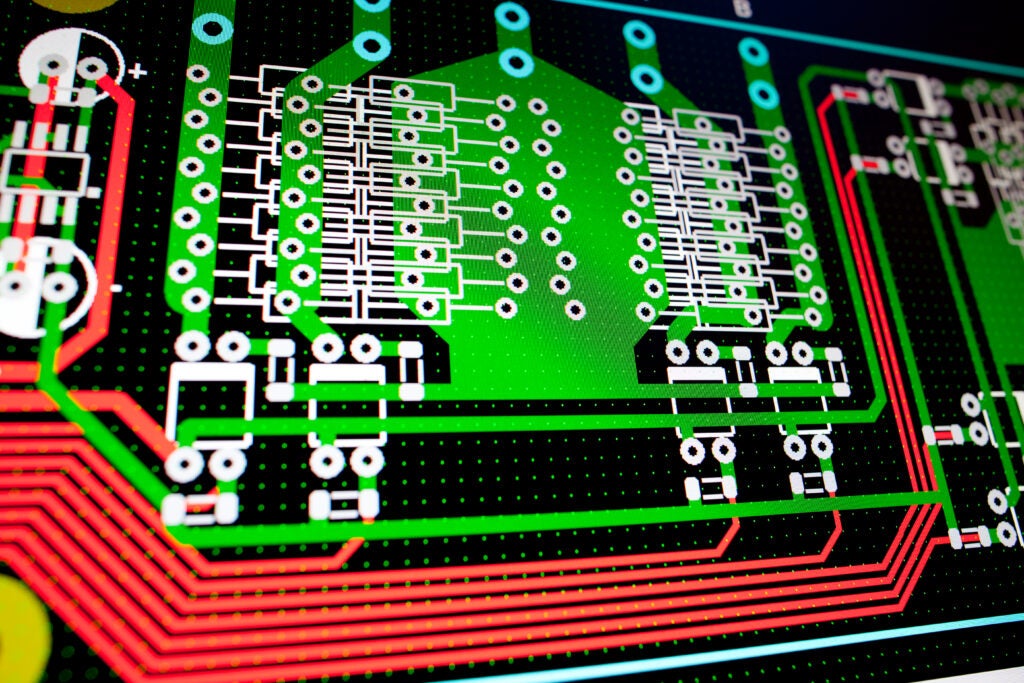

- Constraint Management for Supply Chain Flexibility

Advanced constraint management systems enable designers to build supply chain resilience into their designs. Key capabilities include:

- Automatic configuration of rules based on manufacturer specifications

- Real-time checks for component availability during design

- Alternative component suggestion based on supply chain data

- Design rule verification that accounts for supply chain constraints

- Library Management with Supply Chain Awareness

Centralized component libraries that incorporate supply chain intelligence provide the foundation for resilient design practices:

- Component lifecycle status tracking and EOL notifications

- Preferred parts lists based on supply chain reliability

- Alternative component matrices with qualification status

- Supply chain risk scoring integrated into component selection

Applying proven engineering cost reduction strategies will help you achieve an acceptable level of quality and cost balance. Adding supply chain intelligence to your PCB design and development workflow is the single most impactful set of actions you can take to reach this goal. The degree to which this can be implemented depends on the PCB design and support tools you use. Ensuring you have the best tools for your situation is best achieved by working with the industry leader in supplying engineers with the right tools and support to improve their workflow and maximize cost savings.