Danfoss, a Danish family-owned leader in energy-efficient technologies, set out to explore how artificial intelligence (AI) could transform its PCB design flow as part of its LEAP 2030 strategy. The goal was to test Allegro X AI on low- to mid-complexity boards and see whether AI-driven placement could cut design time while enhancing product quality.

Contact Us

Quick Links

Background

Danfoss is a Danish family-owned company established in 1933 developing energy-efficient technologies for communities and industries.

Goals & Objectives

As part of its LEAP 2030 strategy, Danfoss is looking to tap into the full potential of AI, especially for its PCB design flow. To effectively integrate Allegro X AI into their PCB design process, Danfoss objective was to test an AI-driven PCB layout process for low to mid complexity boards.

“When we are doing a new design, the placement is a pain point in time. It will help us greatly if we could if we could speed that up.”

Torsten Larsen, Lead Consultant, CAD & CAE, Danfoss

Design Information

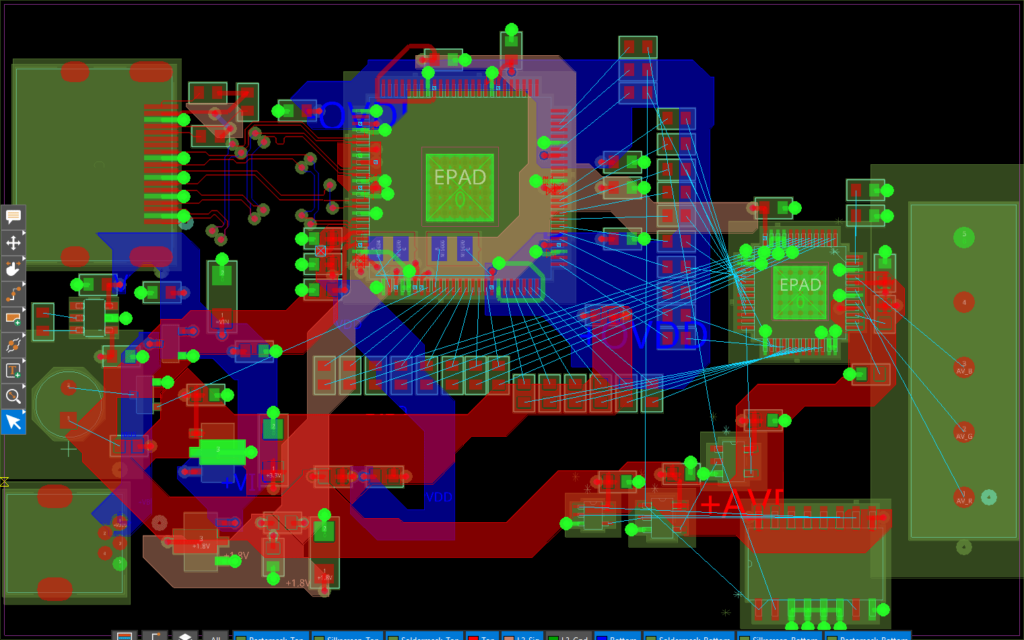

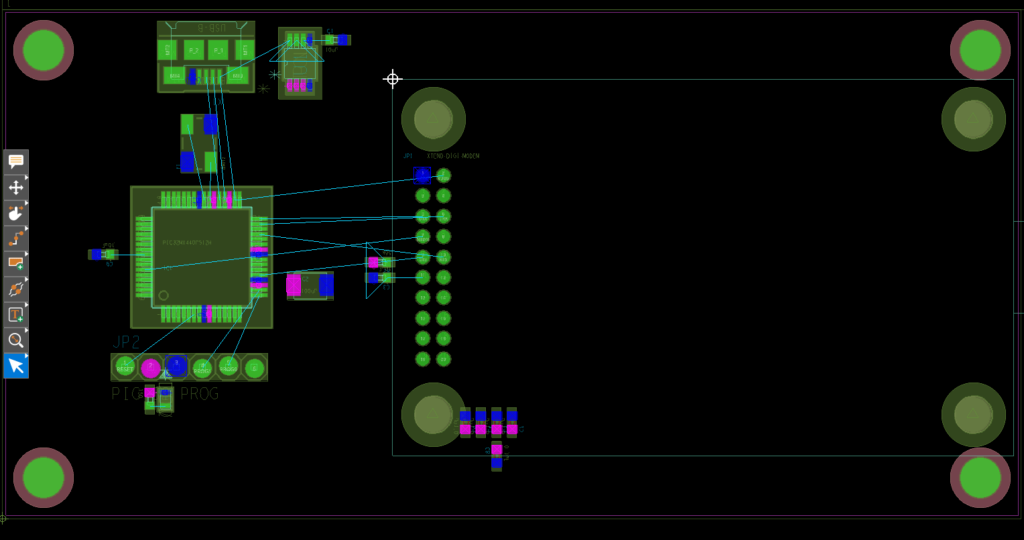

Danfoss will test Allegro X AI on boards between 500 and 1,000 components. The following example outlines the design metrics seen from one of the test boards:

| Parameter | Value |

| Components | 511 |

| Connections | 1759 |

| Pin Density | 86.827 pins/cm2 |

| Board Area | 4 |

| Layers | 26.33cm2 |

| Height Constraint Areas | 2 |

| Power Nets | 20 |

| Ground Nets | 1 |

Approach

Danfoss understood the importance of defining the critical design information which would drive Allegro X AI to produce high quality results. Their approach was to test out Allegro X AI with no input or training, intuitively configuring the guidelines that drive placement, copper pours, and routing. These included:

- Component classes

- Component layer assignments

- Class to class spacing

- Room placement

- Delay and phase tuning

- Advanced routing options

- Routing layer assignments

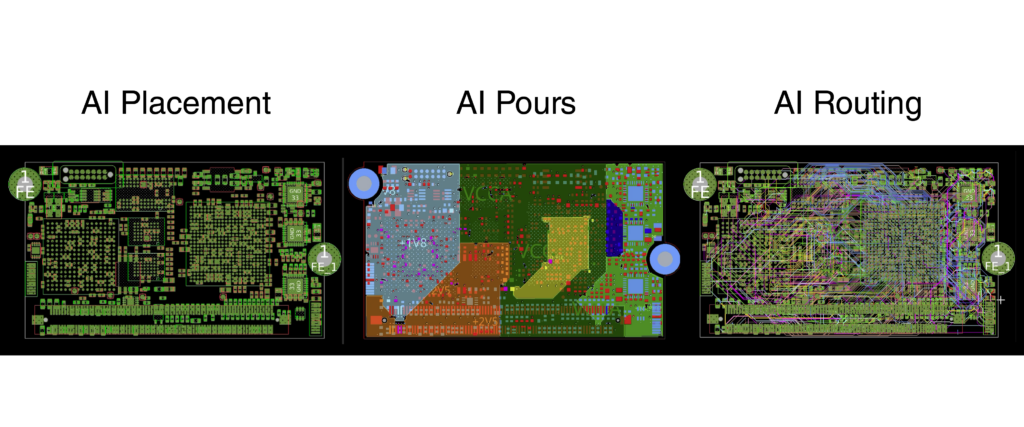

This configuration allowed Allegro X AI to generate an initial component placement optimized for routing and system-level requirements.

Results & Outcomes

“I ended up at the first run with a very nice layout for my design. I’ll say that not much needed to change.”

Bo Kroman, Senior ECAD Engineer, Danfoss

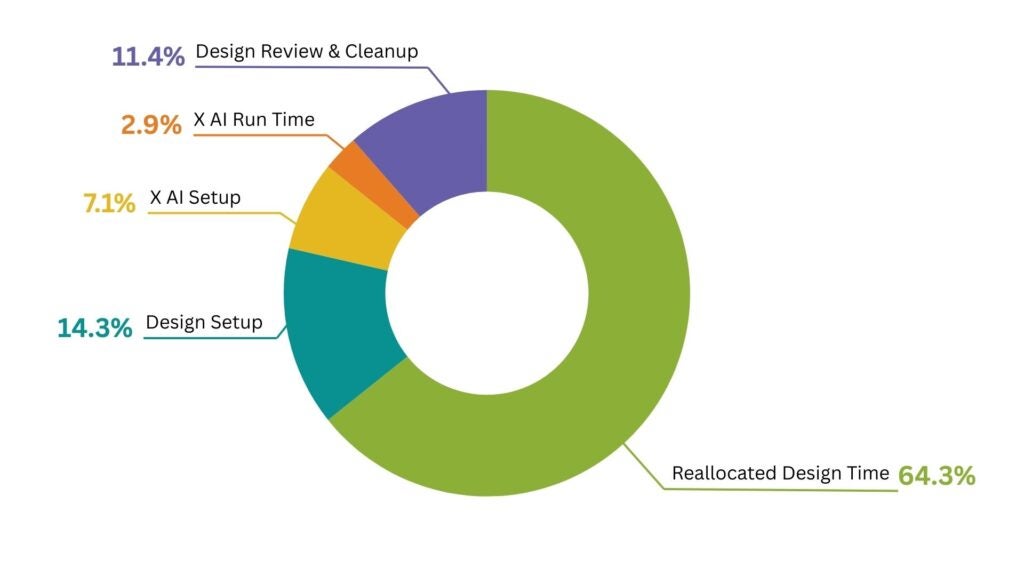

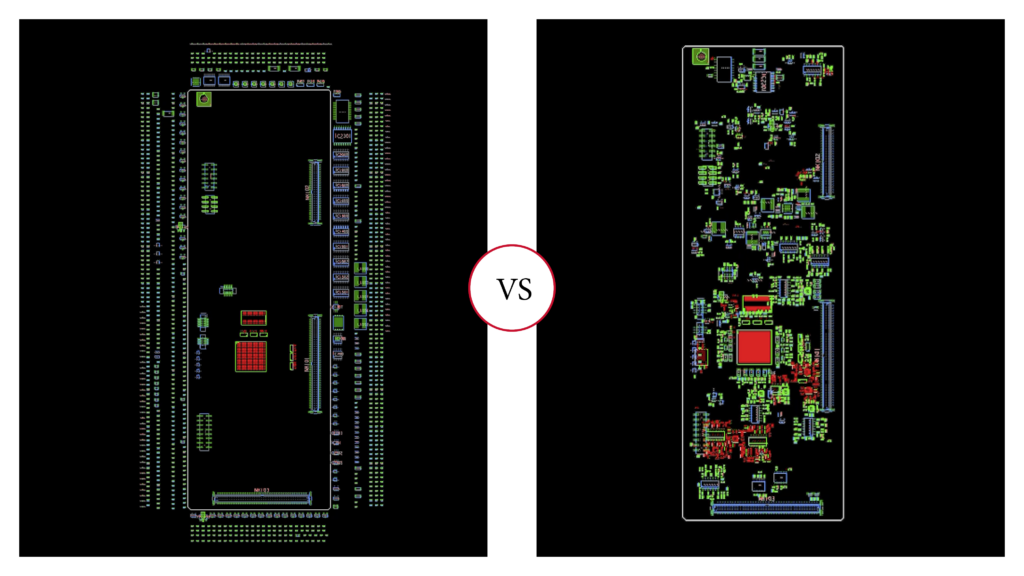

By configuring guidelines for Allegro X AI, Danfoss was able to generate a component placement that was completed quickly, only requiring minimal modifications around the system blocks. With this approach they go from trying to tackle guides for 1,000 components to beginning with a single board with pre-placed system blocks that is optimized for routing. This saves them a lot of time with upfront work and allows them to reallocate design time to improving their designs.

| Task | Manual Time | AI-Assisted Time | Improvement |

| Component Placement | 60 Minutes | 2 Minutes | 96% Reduction |

| Total Process | 70 Minutes | 25 Minutes | 64% Reduction |

While the AI setup added 5 minutes to the standard 10-minute configuration time, this overhead was minimal compared to the time savings Danfoss achieved by incorporating Allegro X AI into their design flow. As seen in the comparison above, Danfoss was able to achieve a 96% reduction in component placement time and an overall 64% reduction in time for the total process.

Insights & Lessons Learned

The first trial of Allegro X AI was successful, subsequent trials across multiple designs confirmed consistent benefits for Danfoss, including:

- Improved placement decisions around ICs

- Shortened connections between components

- Improved decoupling strategy

- Initial routing

- Improved signal integrity with decreased noise across the board

- A more robust power delivery network

- Increased speed of initial component placement for SI/PI analysis

Not only have they accelerated their PCB layout, but Danfoss has also improved signal integrity and power integrity for their designs.

Next Steps

Danfoss has only just begun tapping into the full potential of AI for their PCB designs. In the future, Allegro X AI may be used to optimize their existing designs during respins and continue to improve product quality for their customers

“Since day one, Danfoss has been all about pushing the boundaries of what’s possible, challenging assumptions for how to provide amazing products to customers that help engineer a better future for the world. We believe the potential of using AI is significant”

Alex Hybjerg Clausen, Senior Director, Head of Product Lifecycle Management

By defining key design parameters and letting Allegro X AI generate initial placements, Danfoss quickly achieved high-quality layouts that required only minimal adjustments. The results were clear: faster PCB layout, improved signal quality, and more robust power delivery networks.

This early success shows how Allegro X AI can help Danfoss meet their Leap 2030 strategy, accelerate their PCB design process, and amplify PCB design for energy efficiency.