Company: Simprints Technology Ltd. | Industry: Medical | Solution: OrCAD X

“OrCAD allows us to develop and deploy prototypes really quite quickly. That is the key thing.”

Giles Hutchison, Engineer and Project Manager, SimprintsTechnology Ltd.

About Simprints Technology Ltd.

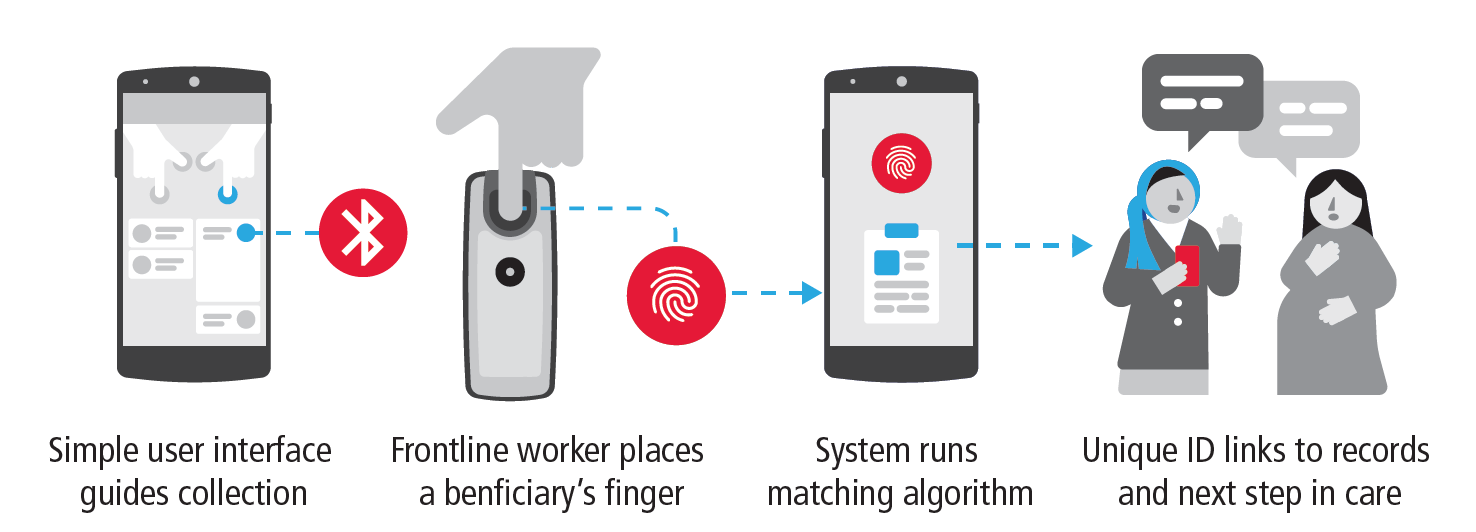

Simprints is a nonprofit technology company founded at the University of Cambridge. The organization aims to eliminate the identification bottleneck in remote and underserved communities by building an affordable, secure, rugged, and open-source fingerprint identification system that works in real-world environments. Aligned with the United Nations Sustainable Development Goals, Simprints supports initiatives in maternal health, education accountability, data collection, microfinance, immunization, and aid distribution. Their technology enables frontline workers to accurately identify individuals—even without formal government-issued IDs—ensuring that critical services reach the right people.

Goals

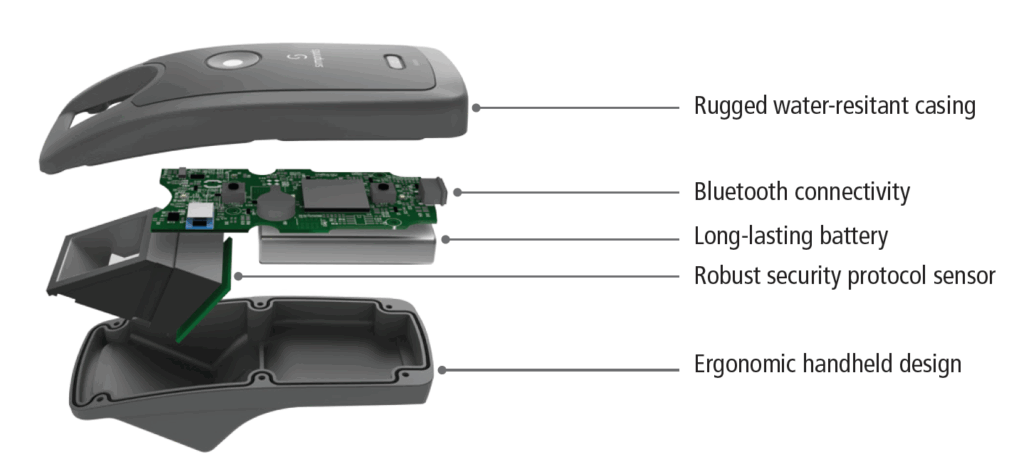

Simprints set out to build a biometric identification system capable of functioning in the world’s most remote and challenging environments. The goal was to create a rugged, secure, low-cost fingerprint scanner that frontline healthcare workers could use with minimal training. This device would provide frontline health care workers, who go door-to-door, access to secure medical records for their patients, enabling them to make critical medical decisions quickly and ensure aid for all those in need. The system needed to operate reliably in deserts, monsoon climates, rainforests, and mountainous regions while supporting global health and humanitarian initiatives aligned with the United Nations Sustainable Development Goals.

Challenges

Simprints Technology aimed to accelerate product development and maintain flexibility in design to adapt quickly to field feedback and certification requirements; however, designing hardware for extreme real-world conditions presented significant engineering hurdles:

Extreme Environments

One of the main challenges was to create a device that would function properly and reliably in extremely remote and harsh conditions. These devices would be frequently exposed to water, dust, heat, drops, and rough handling during transport in jeeps, backpacks, and field kits. The device created would need to be robust.

Power

For Simprints’ fingerprint scanner, power conservation was crucial. The lithium-ion battery needed to last up to two full days on a single charge while maintaining Bluetooth connectivity to mobile phones.

Security

Security was equally essential—biometric data is highly sensitive, and the system had to ensure that fingerprint templates were securely matched to unique IDs without storing personal data.

While addressing these challenges, Simprints Technology needed to maintain low production costs and quickly implement design modifications based on fieldworker feedback and evolving certification standards.

Results

“OrCAD is a widely recognized as an excellent piece of software if you design consumer or industrial embedded electronic products. I have used other less capable but simpler packages, but really, if I’m working on schematic capture, I end up using OrCAD. I never considered using anything else for our designs.”

Giles Hutchison, Engineer and Project Manager, SimprintsTechnology Ltd.

By leveraging OrCAD X technology, Simprints was able to move rapidly from concept to deployable product.

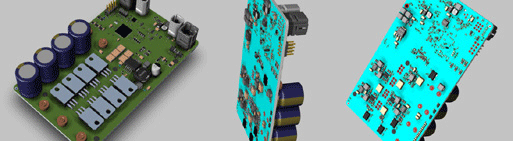

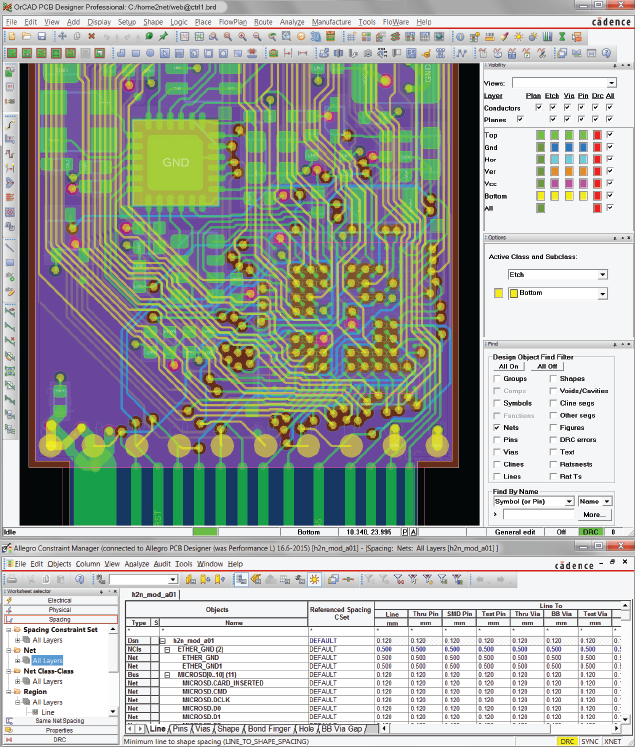

OrCAD X Capture

OrCAD X Capture enabled efficient schematic design and fast iteration, allowing the team to meet environmental standards and achieve CE and FCC certifications with minimal disruption.

PSpice

PSpice Designer helped optimize component choices for performance in extreme conditions within the same CAD environment, saving time.

OrCAD X PCB

Leveraging OrCAD X PCB, allowed Simprints Technology to move from a concept to an actual product and supported low-power, low-cost design objectives.

As a result, Simprints successfully accelerated prototype development and deployed approximately 250 units into the field, empowering frontline workers with reliable biometric identification technology. The partnership with Cadence allowed Simprints to accelerate innovation, maintain flexibility in design, and continue expanding their life-saving impact worldwide.

“OrCAD allows us to develop and deploy prototypes really quite quickly. That is the key thing. It allows us to evaluate technology. System-level design is outside the schematic capture world- that’s more about engaging with partners, evaluating different technologies and components and modules- but we use OrCAD to integrate, allowing us to move on from a concept to an actual product. That’s what OrCAD will do for us.”

Giles Hutchison, Engineer and Project Manager, SimprintsTechnology Ltd.

Learn more about the importance of Simprints’ work of saving lives and how they leverage Cadence to create reliable products with the full story here.