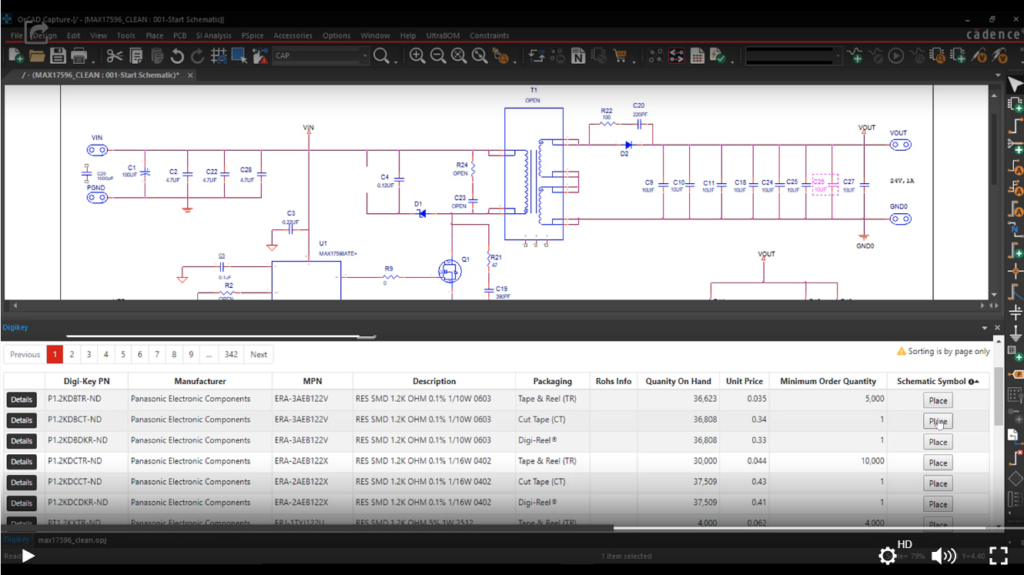

When components are manufactured, their values are guaranteed within a specific range or tolerance. If a component value varies too much, it can be detrimental to the functionality of your design. Since the actual component value can vary per component, this can be very time-consuming to troubleshoot in the lab. This results in a trial-and-error approach with constant swapping of components until the desired results are achieved.

To avoid these issues, a worst-case analysis must be performed in addition to the typical ideal simulation. Worst-case analysis in PSpice simulates the worst probable circuit output by varying component tolerances, ensuring your board will function even with non-ideal component values.

Easily determine if any component tolerance adjustments need to be made up-front and ensure circuit functionality regardless of variations in component manufacturing with the integrated Worst-Case Analysis in PSpice.

Learn how to perform worst-case analysis with our free workshop: PSpice Advanced Analysis Workshop: Level 1