Power Distribution Network (PDN) simulation is a critical part of the electronic design process, ensuring reliability, thermal management, and signal integrity. Furthermore, with even smaller devices and ever-increasing design parameters, designers are now facing increasing challenges in maintaining efficient and stable power distribution. Leveraging PDN simulation can significantly aid in the design process, reduce development time, and mitigate risks related to overheating, electromagnetic interference (EMI), and voltage fluctuations.

- We’ll also be focusing on Cadence’s Celsius suite. Notably, the Celsius Thermal Solver and Celsius PowerDC which empower designers with integrated electrothermal co-simulation, improving speed, accuracy, and insight.

What is a PDN?

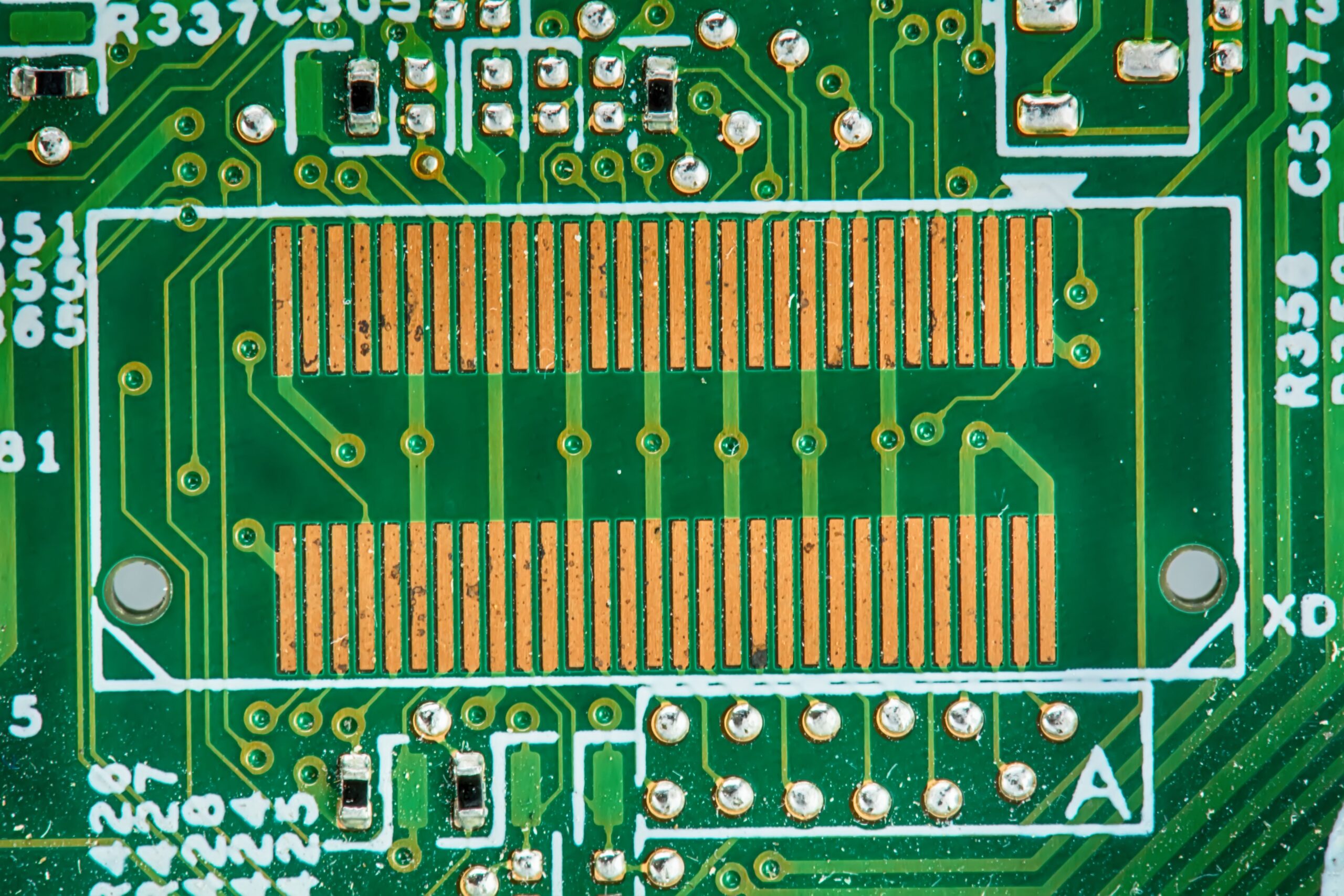

A Power Distribution Network (PDN) encompasses the entire pathway by which electrical energy is delivered from a power supply to the various components within a PCB. This network typically consists of voltage regulators, capacitors, inductors, connectors, planes, vias, and traces. Its primary function is to supply a consistent and stable voltage and current to all the active components on the PCB, ensuring optimal performance and reliability.

- Cadence’s PowerDC enables DC voltage and joule-heat co-simulations, identifying IR drop and thermal stresses.

Importance of PDN in Electronic Design

Poorly designed PDNs lead to voltage drops, excessive heat, and signal integrity issues, potentially causing system failures and costly redesigns. PDN issues can manifest in several ways, including:

- voltage ripple

- transient noise

- ground bounce

- thermal hotspots

Each adversely affects device functionality and lifespan. Cadence’s Celsius Thermal Solver addresses these issues by simulating steady-state and transient power-induced heating across PCBs and enclosures using highly parallelized FEA and CFD analysis. This ensures:

- Reliable power delivery under varying operational conditions.

- Minimization of voltage fluctuations and transient spikes.

- Improved thermal management and reduced heat dissipation issues.

- Enhanced signal integrity, reducing EMI susceptibility.

Leveraging PDN Simulation for Optimal Performance

PDN simulation involves computational modeling to analyze how well a PDN delivers power under various conditions. It allows engineers to predict and optimize the performance of power distribution networks early in the design process. Major simulation types include the following:

| Major Types of PDN Simulation | ||

| Simulation Type | Description | Benefits |

| Voltage Drop Analysis |

|

Maintains voltage within acceptable limits, ensuring reliable component performance. |

| Thermal Management |

|

Improves thermal dissipation through optimized layouts or cooling measures, enhancing device reliability. |

| Inductance and Capacitance Optimization |

|

Minimizes impedance, enhances transient response, and improves overall efficiency. |

| Noise and EMI Reduction |

|

Reduces electromagnetic emissions, improves signal integrity, and ensures regulatory compliance. |

Steps to Optimize Your PDN Design Through Simulation

| Step | Description | Key Actions / Considerations |

| 1 | Define Simulation Objectives |

|

| 2 | Establish Accurate Simulation Models |

|

| 3 | Initial PDN Analysis |

|

| 4 | Implement Design Improvements |

|

| 5 | Re-simulate and Iterate |

|

| 6 | Final Validation |

|

Celsius For PDN Design

Cadence’s Celsius Thermal Solver and Celsius PowerDC integrate into PDN design workflows and enable PDN simulation by providing simultaneous electrical and thermal co-simulation.

Celsius enables designers to visualize IR drop and Joule heating concurrently, ensuring accurate identification of thermal hotspots caused by voltage drops. Its scalable simulation capabilities allow quick iterations while maintaining accuracy, helping engineers refine decoupling capacitor placement, copper thickness, and plane structures to achieve optimal thermal and electrical performance.

Additionally, Celsius supports transient thermal analysis and full 3D system-level simulations, enabling engineers to evaluate thermal dissipation strategies and airflow impacts on PDN performance, ensuring reliability and thermal efficiency in high-density designs.