When it comes to PCB design, it is often overlooked how the choices made during the design process can ultimately impact manufacturing results. This is why design for manufacturing (DFM) has become a hot button topic. By keeping manufacturing in mind throughout the design process, engineers can design a board and manufacture it with a high yield count and low defect rate.

When it comes to PCB design, it is often overlooked how the choices made during the design process can ultimately impact manufacturing results. This is why design for manufacturing (DFM) has become a hot button topic. By keeping manufacturing in mind throughout the design process, engineers can design a board and manufacture it with a high yield count and low defect rate.

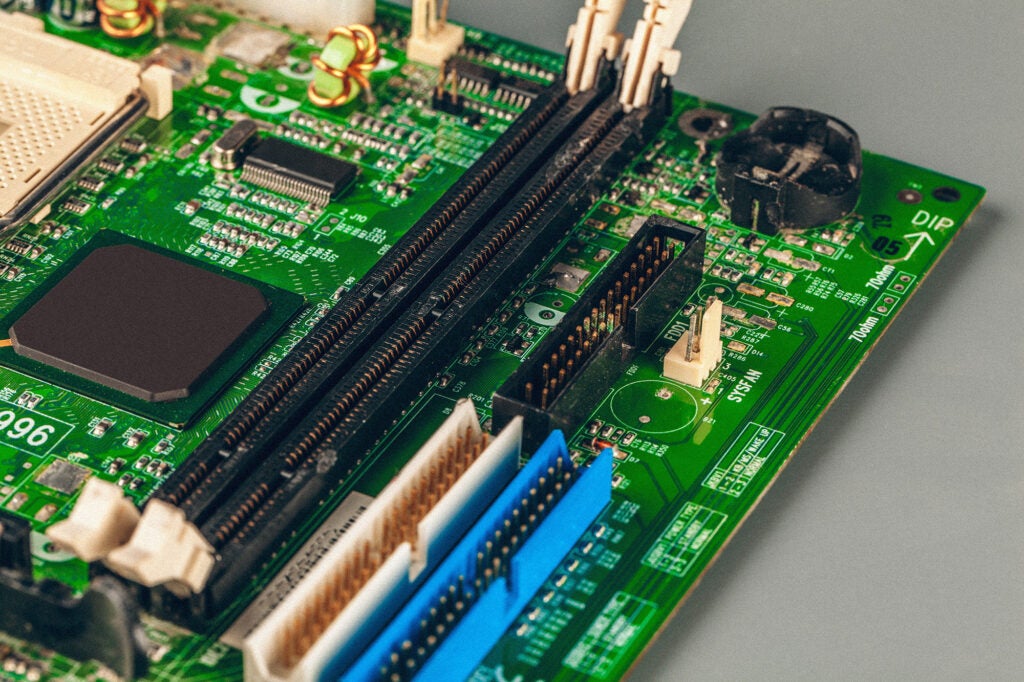

To underscore the importance of design for manufacturing, the students enrolled in the Rochester Institute of Technology (RIT) PCB design course visited the Center for Electronics Manufacturing and Assembly (CEMA) Lab. The CEMA lab performs research and provides local industry services for the Electronics Manufacturing Services (EMS) industry.

According to Dr. Martin Anselm, Associate Professor at RIT, Global President of the Surface Mount Technology Association, and graduate Director of the MMSI Program, the goal of the visit was to gain perspective on the manufacturing process, provide a deeper understanding as to why design for manufacturing is important in PCB design, and how this all ultimately leads to design for reliability. The students were able to tour the lab, see how various processes work, and learn about common problems that occur during board manufacturing.

With electronics and electrical functionalities continuing to evolve at a rapid pace, good DFM is critical as all products are affected by (or at the mercy of) what manufacturers can assemble. The effects of bad DFM can trickle down to not only affect yield and reliability, but also impacts environmental concerns such as waste creation.

“Manufacturing, for years, was there to solve the problems in the design on the fly … What I’m seeing more of is an emphasis for pushback,” said Anselm. “The manufacturers are saying ‘stop sending us these impossible designs because [while] we can make it function at the end of the line with a certain amount of yield, we can’t guarantee the reliability when it gets in the hands of the customer.’”

The goal of the course is to help prepare students for the “real world” of engineering and address these manufacturing issues by blending together their knowledge of electrical engineering and PCB Design fundamentals which typically is only obtained from hands-on experience. At the end of the course students were able to implement engineering concepts learned in their studies to design and manufacture functional PCB designs.

“Our design is really just finding ways to make a product that solves mechanical and assembly problems in the best way possible,” said Kirsch Mackey, PCB Design Educator and RIT Adjunct Professor. “For best design practices, you must have some understanding of what your manufacturer has to go through to make your product. If you don’t, they might not be able to make it and that affects the [end] product. That is why this [knowledge] is absolutely important to be a better designer.”

As the industry evolves, it is great to see institutions like RIT providing this kind of instruction to young engineers, allowing them to develop the skills they need to meet current industry and workplace demands. By offering them this kind of hands-on instruction, they are able to gain the experience and knowledge required to be successful in their careers.

To learn more about the RIT PCB education programs visit: https://www.rit.edu/news/rit-partners-industry-experts-new-curriculum-electronics-design-and-manufacturing