Producing accurate manufacturing data is an essential part the PCB design process. It often includes the creation of several drawings and documents to effectively communicate information required to manufacture and assemble the PCB. This manual creation process includes several steps which may seem tedious or inconvenient at times but is a critical piece of creating a great product.

Three Main Purposes of Documentation

1. To instruct someone on what needs to be made and how

Many times, we throw things at the fabricator or assembler without understanding the contents of what we’re throwing at them. Ask what they need. It is much better to have open communication to remove easily avoidable issues.

2. To program machinery

The fabrication and assembly processes are very automated. Documentation is necessary for the functions of the machines.

3. To verify the end product against the design data

Many things can happen during the 40 plus steps that could affect design functionality and yield. Verifying what was built versus the design intent is crucial in making sure things work properly.

Good documentation will contain all information required to fabricate, assemble, and test the PCB design including the physical characteristics such as size, drill information, BOM, fabrication/assembly drawings and more. Proper manufacturing preparation and data management helps avoid miscommunication, unnecessary respins, and manufacturing delays. Therefore, designers must be aware of documenting the right information, in the right way, to successfully manufacture their final product.

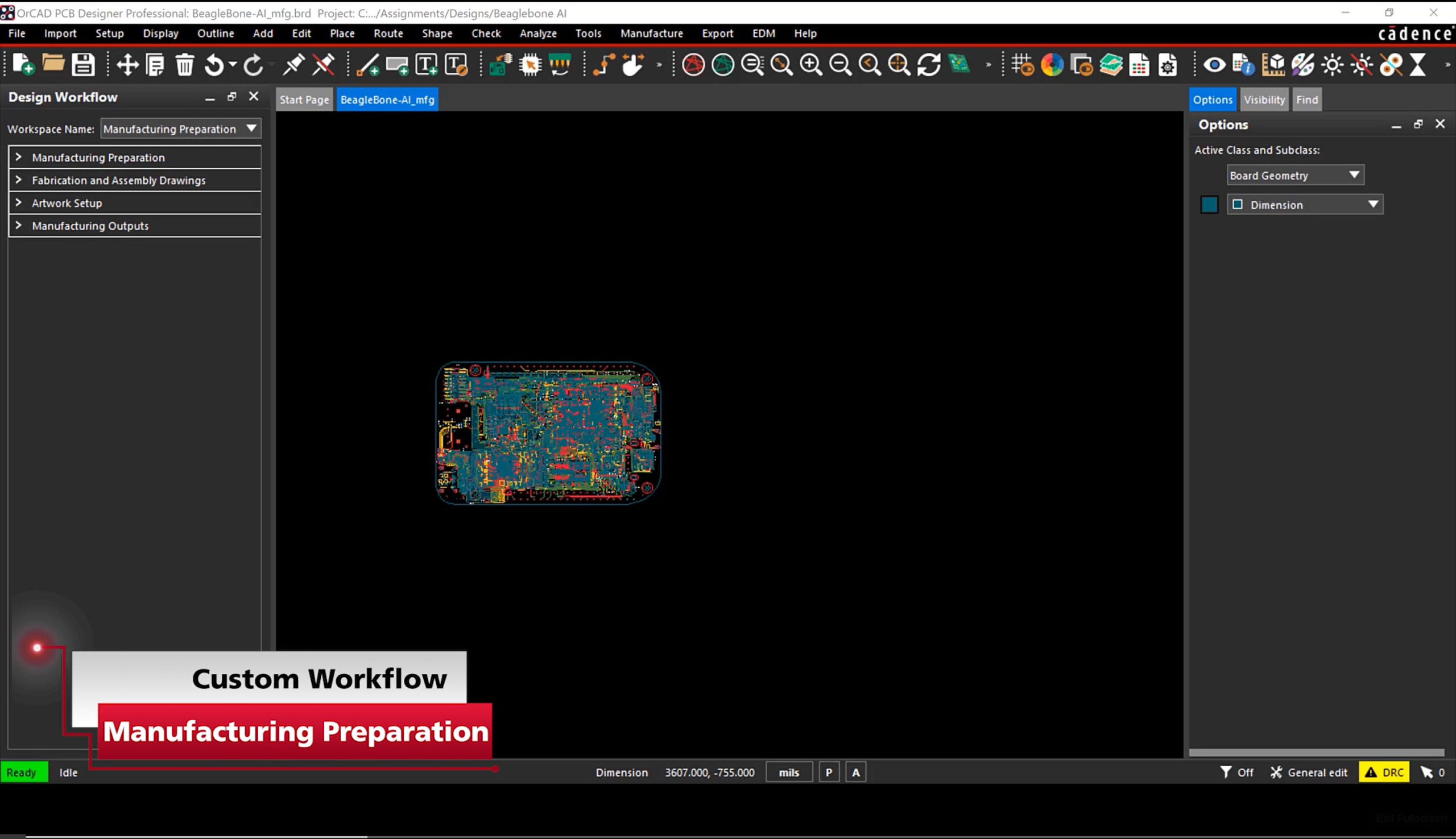

Introducing Manufacturing Prep Custom Workflow

Inconsistencies in your design process can result in documentation errors, confusion for your PCB suppliers, and delays in the manufacturing process. Providing reliable and accurate manufacturing documentation is crucial for fabrication, assembly, and testing of your PCB.

With EMA Design Automation’s Manufacturing Prep Custom Workflow, you can easily create reliable and consistent manufacturing documentation. The pre-defined template provides streamlined access to the steps required to create manufacturing documentation such as: automatic test points, silkscreen generation, steps to create fabrication and assembly drawings, artwork setup, and common manufacturing exports.

With EMA’s custom workflow, you’ll create consistency throughout your design process and successfully produce the manufacturing data required for the fabrication, assembly, and testing of your PCB.

To download this free product, visit our e-store: https://store.ema-eda.com/pcb-products/manufacturing-prep-custom-workflow/