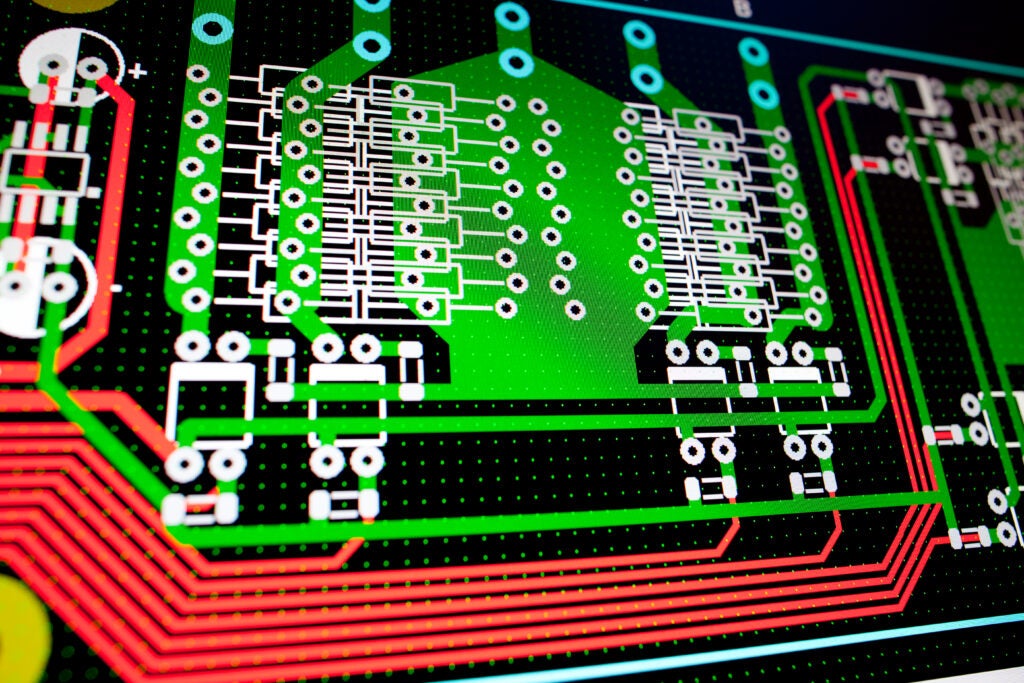

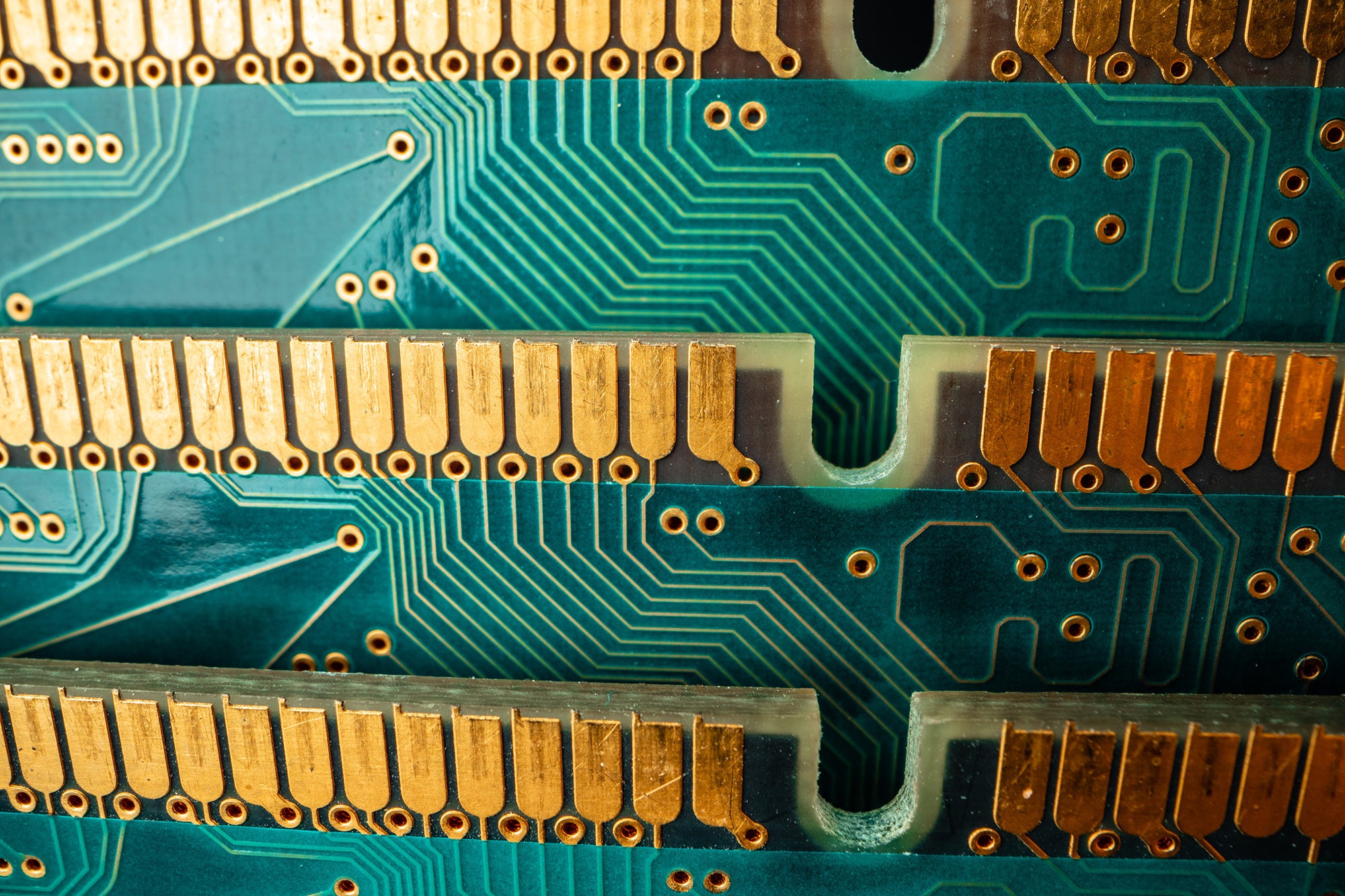

One of the most difficult tasks for PCB designers is laying out the board. Finding the optimal location for components and traces is also the most time-consuming. These challenges are multiplied for dense boards and/or when there are high trace counts, such as with PCIe intraboard communication. For these and other use cases, following differential pair routing guidelines is essential.

Differential Pair Routing Essentials

Engineers usually have several routing topologies in their tool bag. However, there is often a more basic choice to make: Should single-ended or differential signal routing be used? In many cases, input-output requirements and board density dictate that differential pairs be used. In these cases, it is critical to follow differential pair routing guidelines, as listed below.

|

IMPORTANT DIFFERENTIAL PAIR ROUTING GUIDELINES |

|

|

Guideline |

Why It’s Important |

|

Make sure impedance is constant along traces |

Impedance matching is critical for differential signal propagation. For maximum power transfer, the source impedance must match the load impedance (resistances equal in magnitude and reactances equal and opposite in polarity) and the characteristic impedance of the line must match the load impedance. |

|

Use the same copper width for each pair trace |

Material differences between traces translate into impedance mismatch. |

|

Keep pair trace lengths equal |

Unequal traces will create reflection along transmission lines, which degrades transmitted signal strength. |

|

Maintain equidistance between traces |

Spacing is critical for impedance matching and to avoid signal degradation and/or reflections. |

|

Isolate differential pairs from other traces |

Keeping differential pairs adequately spaced from other traces minimizes or eliminates potential coupling that can introduce or increase electromagnetic interference (EMI). |

|

Avoid routing around other board elements |

Routing around components, via annular rings, or other board elements makes it difficult to keep trace lengths equal. Often, techniques like meandering–which may be limited to specific angles–must be deployed which may introduce some mismatch. |

|

Use broadside routing for adjacent layer traces |

For high-density boards, it is often necessary to run differential pairs on inner layers through vias. Doing so often requires adjusting return path voiding to maintain impedance balance. |

As this list indicates, symmetry is critical for routing differential signals. As this can be challenging, it is important to know when these guidelines should be employed.

Should You Use Differential Pairs?

As mentioned, trace routing can be predisposed due to external connections and/or space limitations. Nevertheless, it is important to know the advantages and disadvantages of differential trace routing.

| Advantages | Disadvantages |

|

|

Clearly, there are signal integrity benefits to using differential pairs in your PCB layout. Yet doing so does necessitate that you are able to implement differential pair routing guidelines, which can be a challenge.

Ensuring Differential Pair Guidelines Are Met

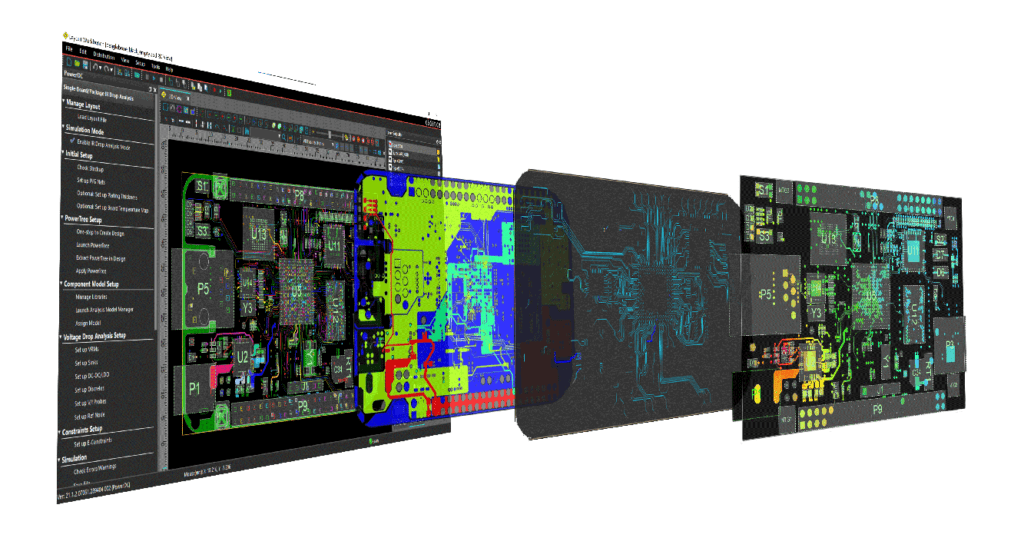

Your ability to satisfy the requirements for differential pair routing–at least, within a reasonable design and development time interval–is virtually proportional to the quality of the PCB design software tool(s) you use.

How to Best Employ Differential Pair Routing Guidelines

- Route differential pairs on your schematic diagram to aid in simulation and facilitate conversion to the board layout.

- Understand how to accurately set and organize routing constraints for your EDA tool.

- Employ PCB design software with advanced routing capabilities; such as automatic and AI routing to minimize the need for manual correction.

- Run DRC checks often and perform real-time route analysis.

- Use simulation software to analyze your layout design for optimal signal integrity.

There are significant advantages to differential pair routing and with the right software you can ensure your design achieves these benefits.