Whether you are at work, the mall, a park, or traveling, people are just as likely to use a mobile device as they are talking face-to-face. And the level of reliance on cellphones, tablets, laptops, and other products continues to increase. Therefore, ensuring the accuracy of signal processing within and between mobile devices and peripherals is a critical concern for electronics designers and developers.

Since its founding in 2003, the Mobile Industry Processor Interface Alliance, or MIPI Alliance, has been the leader in developing specifications for mobile device interoperability. These technical specifications, directed at software and hardware, have evolved into the principle design and development standards for interface operation in mobile electronics systems. Today, MIPI standards compliance is virtually mandatory for your PCBA or device to be widely accepted and implemented.

What Are the MIPI Standards?

Alliance members develop MIPI specifications to maximize the performance of mobile-connected devices by supporting and improving operations in the following areas.

Goals of MIPI Standards

- Minimize electromagnetic interference or EMI

- Lower power consumption, such as for cellular low-power IoT

- Improve high-bandwidth–like UWB technology–application operation

Specifications are available that target multimedia, chip-to-chip or interprocessor communications (IPC), software integration, debugging, data management, device control, and physical layer interface concerns. Physical layer or MIPI PHY standards are foundationally important for designing and developing mobile devices and systems.

MIPI specifications have evolved into primary standards that guide the design and development of mobile electronics, ensuring compatibility and versatility within the industry.

Why Are MIPI PHY Standards Important?

MIPI PHY standards fall under one of the categories listed below.

|

MIPI PHYSICAL LAYER SPECIFICATIONS |

||

|

PHY SPECS |

Features |

Uses |

|

A-PHY |

32 Gbps data rate Point-to-point or daisy chain topologies Automotive EMC affects immunity. |

|

|

A-PHY PALS |

Long reach A-PHY SerDes A packet transmission and reception. |

ADS, ADAS, and IVI. |

|

C-PHY |

Low EMI. Low power. High-performance. |

Displays and cameras for smartphones, tablets, surveillance cameras, automotive sensors, IVI, IoT, robots, and drones. |

|

D-PHY |

Low EMI. Low power. High-performance. |

Smartphone cameras and displays, automotive cameras, dashboard displays, radar sensors, large tablets, robots, and drones. |

|

M-PHY |

Low EMI. Low power. High bandwidth. |

RF interface. UFS memory. Processor-to-processor communication. |

Each of the specifications categories above supports the MIPI objectives and defines characteristics and parameters for an aspect or type of mobile-connected device operation.

A-PHY

SerDes specification for advanced automotive technology and other applications. A-PHY incorporates downlink speeds of 2-16 Gbps, uplinks of 100 and 200 Mbp, extremely high immunity to automotive environment electromagnetic compatibility (EMC), daisy chain or point-to-point topology, and 15 m capability.

A-PHY PALS (Protocol Adaptation Layers)

A-PHY PALS supports and promotes the use of MIPI A-PHY for advanced automotive applications. A-PHY PALS is designed to allow for easy integration of in-vehicle innovations.

C-PHY

C-PHY specifications are for cameras and displays used in mobile-connected systems, such as smartphones, tablets, IoT, and surveillance cameras. C-PHY supports previous MIPI CSI-2 (camera & imaging) and MIPI DSI-2 (display) standards.

D-PHY

Similar to C-PHY, D-PHY targets displays and cameras to promote high performance while minimizing noise interference and power. Differential signaling protocol specifications for 4 meter or less interconnection.

M-PHY

M-PHY includes multimedia and IPC communication interface specifications and promotes the efficient design of mobile systems for high bandwidth, low power, and minimal EMI operation.

Electronic circuit boards and systems that adhere to these MIPI standards help ensure the agnostic integration of products from manufacturers around the globe. You must comply with these standards to ensure the marketability of your mobile product is maintained.

How to Ensure MIPI Compliance for Your Device?

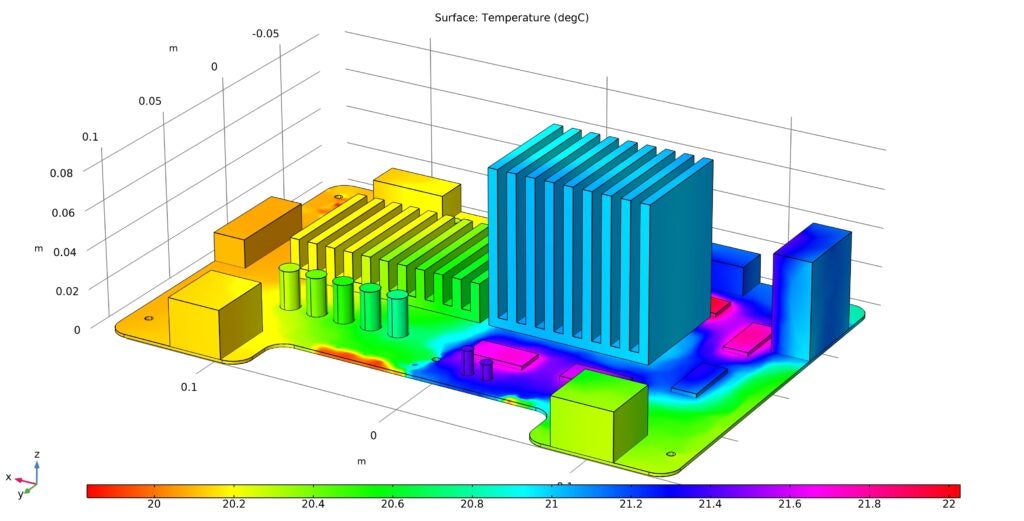

Achieving MIPI compliance is a complex process. However, the MIPI standards specifications provide clear guidance and criteria for testing and validating that your PCBA or mobile-connected electronic device meets the necessary requirements. As shown below, awareness and understanding of pertinent MIPI standard(s) for your design are the first of the best practices you should follow to achieve compliance.

|

Guidelines for MIPI Compliant PCBA Design

|

Although passing the appropriate MIPI defined test regimen enables you to label and market your product as compliant to the standard, failing to do so can have significant negative repercussions. These include the extra time and costs of repeating much of the PCB design process and rebuilding and retesting. The best way to avoid these contingencies and the damage to your project schedule and budget is to employ a MIPI compliance testing software tool during design. Learn more about how to perform MIPI compliance verification during the PCB layout with this e-book.

Sigrity allows you to verify that your design adheres to the specifications of the appropriate MIPI standard before the board build. This tool also easily integrates into your PCBA design process enabling you to optimize development and maximize ROI.

EMA Design Automation is a leading provider of the resources that engineers rely on to accelerate innovation. We provide solutions that include PCB design and analysis packages, custom integration software, and engineering expertise, which enable you to create more efficiently. For more information on the MIPI standards and how we can help you or your team innovate faster, contact us.