There was a time when you almost had to be an IT professional to hook up a computer and peripherals. A home network? Forget about it! Fortunately, those days are long gone, and a big reason for this is the universal serial bus or USB technology.

USB is the most common means of connecting mice, keyboards, external drives, printers, and other peripherals to PCs and Macs. Additionally, USB is the cable of choice for smartphone chargers, PC cameras, camcorders, A/V equipment, and many other applications.

This widespread usage, coupled with many USB component and cable manufacturers, places a high premium on interconnectivity and quality assurance. To ensure these challenges are met, USB compliance testing is utilized. All USB designers and engineers should know what, why, and how this verification process is implemented.

USB Compliance Standards

Ensuring USB components reliably connect and communicate with each other and other electronic devices is the purpose of the USB Compliance Program, created and managed by USB-Implementers Forum, Inc. Along with member companies, this organization creates the standards to which USB devices must adhere to become certified. USB specifications for which compliance standards are developed have gone through three major evolutions, as shown below, since the introduction of the technology in 1996.

|

USB COMPLIANCE EVOLUTIONS |

|||

|

Released |

Specification |

Revisions |

Max Speed |

|

1996 |

USB 1 |

1.0 1.1 |

12 MBps |

|

2000 |

USB 2 |

2.0* |

480 MBps |

|

2008 |

USB 3 |

3.1 (Gen 1 & 2) 3.2 (Gen 1 & 2) 3.2 (Gen 2×2) |

20 Gbps |

|

2019 |

USB 4 |

1.0 2.0 |

80 Gbps |

* There was a USB 2.0 revision in 2007; however, the maximum speed remained the same.

USB was developed to simplify the data transfer landscape, where virtually many devices had proprietary interfaces and cable requirements. This standardization has revolutionized data transfer among computing devices and simplified connecting electronic devices and equipment to the point that almost anyone can do it.

USB has also been significant in enabling and promoting faster and more reliable digital communication. The foundation upon which this application expansion rests is compliance, which is assured by experimental verification and compliance testing. However, achieving USB compliance can be a significant hurdle to overcome.

For example, redesign and respins are usually required if your product fails USB compliance testing at one of the USB-IF Platform Interoperability Labs (PILs), plugfests or plugtests, or independent testing laboratories (ITLs). These additional development costs can quickly balloon and substantially negatively impact profitability and ROI.

Luckily, avoiding these contingencies is possible by incorporating compliance testing into your PCB design process and following good guidelines, as is done for DFM and DFA.

USB Compliance Testing Optimization

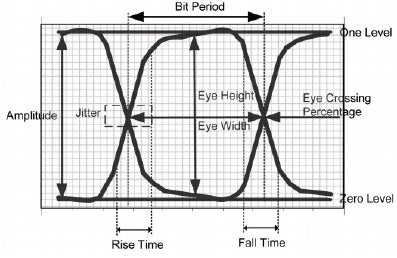

USB-IF provides detailed specifications, procedures, and preferred testing equipment information to promote homogeneity among verification procedures. USB standards publications also give explicit parameters and conditions that must be verified. Knowing and understanding this information is the first step in optimizing your USB compliance testing process.

How to Optimize USB Compliance Testing

|

|||||||

By knowing what USB compliance is, why it’s essential, and how to optimize your USB compliance testing process, you can avoid development delays, multiple physical tests, high costs, and factors that will make it much more challenging to maximize profitability and ROI for your PCBA or electronic product.

EMA Design Automation is a leading provider of engineering resources that accelerate innovation. EMA Design Automation provides solutions that include PCB design and analysis packages, custom integration software, and engineering expertise, which enable you to create more efficiently. For more information on USB compliance testing and how we can help you innovate faster, contact us.