The PCB design process is both an art and a science. Transforming an idea or set of performance objectives into a canvas or schematic that is true to the original inspiration or intent requires creativity. Yet, designing a circuit board that leverages and must adhere to the laws of physics, which includes conservation, transfer and conversion of energy, requires scientific or engineering ingenuity.

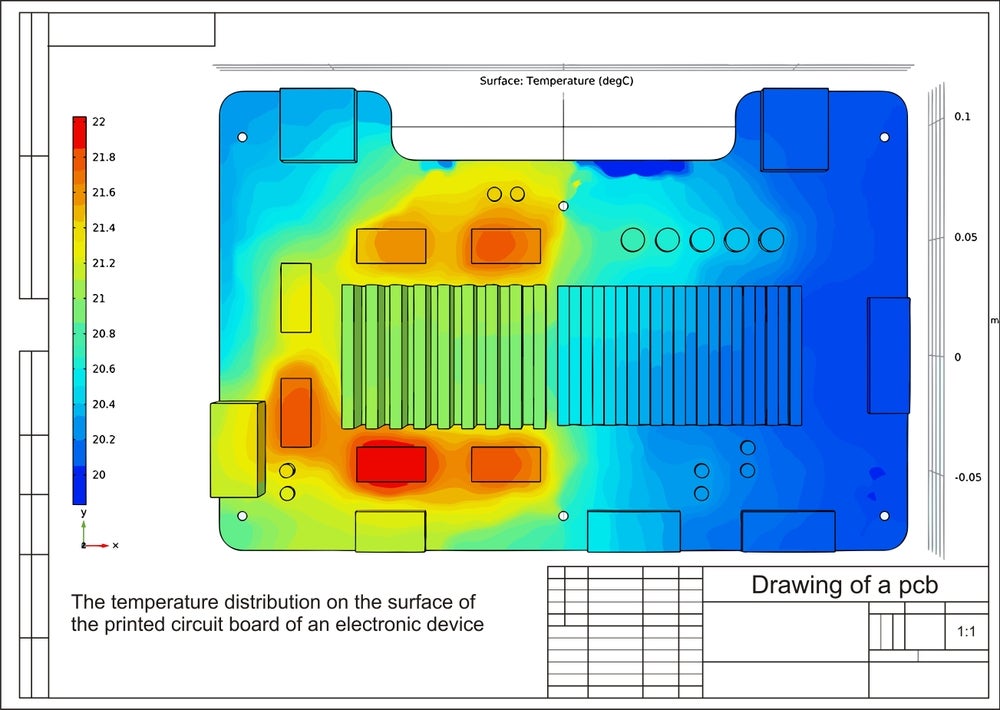

Today, the complexity of many PCBs; such as multilayer designs, mandate an effective EDA program is used. PCBA design programs have the same basic capabilities, like automatic component placement and trace routing. However, the most efficient board development requires more advanced functionality; such as thermal analysis and reliability assessment. And employing the best software for design and simulation is the key to optimizing your PCBA development for quality, time and cost.

The Best Software for Circuit Design and Simulation

PCBA design software is essential for designing the electronic circuits that are utilized in virtually all industries. As a result, designers and engineers have many PCB CAD software programs from which to choose. Unfortunately, the majority of these tools have limitations that restrict their applicability for common problems that PCB designers face. In those cases, it is necessary to look to more advanced product design and development software solutions.

The principal limitation for PCBA design programs is the inability to perform the simulations, which are critical for advanced analyses and development optimization. This shortcoming can be overcome by incorporating software that possesses attributes, as listed below.

|

CAPABILITIES OF THE BEST SOFTWARE FOR CIRCUIT DESIGN AND SIMULATION |

||

|

Capability |

Description |

Circuit Design Benefit |

|

Reliability Analysis |

The stress testing of a component(s) to determine the electrical/thermal conditions under which operational and mechanical breakdown will occur. |

Determine, before manufacturing, if component(s) will satisfy performance objectives; such as adequate power dissipation, and operate reliability over its projected lifecycle once installed and powered up. |

|

Analog Optimization |

The evaluation of a circuit’s analog signal(s) approximation of a target performance curve. |

Efficient tuning of circuit behavior to match performance objects. |

|

Monte Carlo Simulation |

Statistical analysis of a component or circuit’s behavior over a range of possible scenarios. |

Determine optimal behavior parameters and estimate mass production yield. |

|

Parametric Sweep Analyses |

The ability to model component(s) and circuits in various domains and sweep single or multiple parameters simultaneously. |

Feasibility testing and identification of the set of parametric values that provide optimal solution. |

|

Sensitivity Analyses |

The ability to evaluate components and circuits for worst-case scenarios and fine tune tolerances. |

Determine yield and which components are more impactful on it. Optimize circuit design for maximum cost-effectiveness. |

Not all board designs need each of the circuit design simulation capabilities shown above. Nor is this list exhaustive. However, employing a software tool with these capabilities for circuit design and simulation provides you with a comprehensive PCB design solution that will aid you in optimizing your design for efficiency, quality, speed and cost.

Choosing the Best Simulation Software for Your Design

The best software for circuit design and simulation is the one that most closely matches or exceeds your development needs. Determining which product meets this criteria is best done by following a set of guidelines, as listed below.

Best Software for Circuit Design and Simulation Selection Guidelines

- Define PCB design areas to target for optimization

Identifying which specific aspects of your design process that need to be improved is an essential first step in selecting the best software tool. - Verify the software performs required simulations

Ensuring that your chosen solution will integrate with your EDA program and is capable of performing the specific simulations needed is critical. - Opt for a solution that is scalable

Continually changing software solutions can increase development time, instead of

optimize. Choosing a solution that will grow as your needs change can mitigate this

issue. - Make sure your product design software tool is well supported

The level of resources and support available should be a primary consideration for any

EDA support software tool, as it can significantly affect the learning curve and overall

efficiency.

The most comprehensive software simulation solution that satisfies these guidelines is the PSpice Designer option. In addition to having an extensive simulation model library of components that are editable and easily integrated capabilities; PSpice simulation software can scale to include advanced capabilities to optimize your circuit designs, such as Smoke Analysis, Monte Carlo Analysis, Sensitivity Analysis, Parametric Plotter and Analog Optimizer. Fully leveraging the many benefits of PSpice is best done by partnering with an industry leader in supplying and supporting PCB design product development software solutions.

EMA Design Automation is a leading provider of the resources that engineers rely on to accelerate innovation. We provide solutions that include PCB design and analysis packages, custom integration software, and engineering expertise, which enable you to create more efficiently. For more information on how to select the best software for circuit design and simulation for your project and how we can help you or your team innovate faster, contact us.